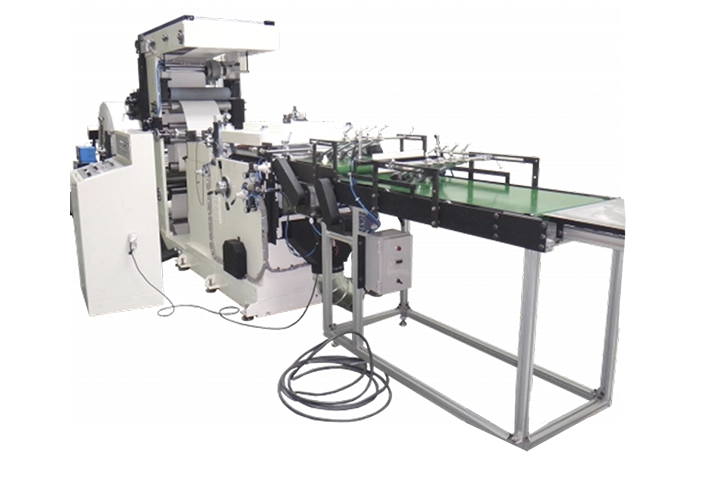

Machine d’impression flexo et de découpe

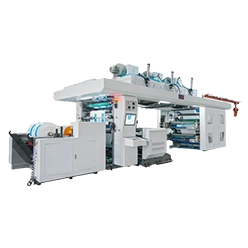

Flexo Printing and Die-Cutting Machines are two different industrial machines commonly used in packaging production, labeling, printing, and similar sectors. Often integrated into a single system, they perform multiple processes simultaneously. Their functions are explained below.

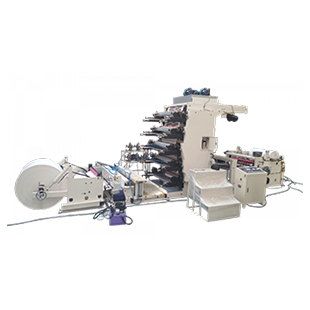

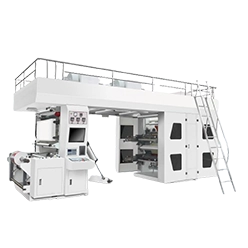

Working Principle of Flexo Printing Machine

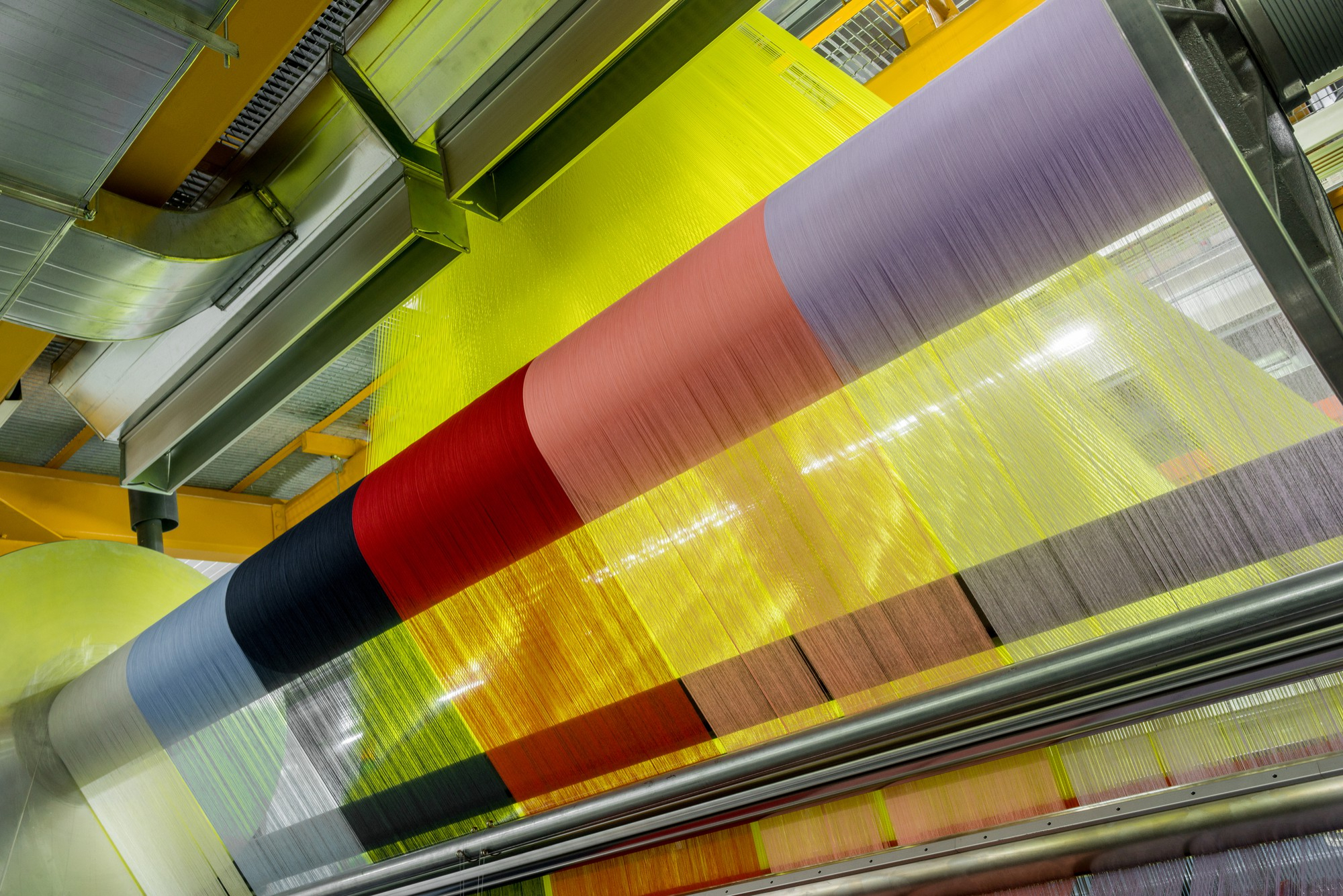

Flexo printing (flexography) is a printing method capable of printing on flexible and durable materials. Flexo printing machines transfer ink via flexible printing plates. This printing technique is widely used in the packaging industry, especially for printing on plastic, paper, cardboard, aluminum foil, and other flexible materials.

Flexible plates: Flexo machines use flexible plates, usually made from photopolymer materials, to transfer ink onto the printing surface.

Ink transfer: These plates transfer inks in various colors to a cylinder or directly onto the printing substrate. Unlike offset printing, the flexo plate directly contacts the substrate to apply the ink.

Versatile surfaces: Due to their flexibility, flexo plates can print on flat, cylindrical, round, and even irregular surfaces.

Advantages: It offers fast printing processes, a wide range of color options, applicability on different materials, and the ability to work with eco-friendly inks.

Applications: Packaging sector (food, cosmetics, pharmaceuticals, etc.), label printing, paper and plastic products, outdoor advertising, and signage.

Working Principle of Die-Cutting Machine

Die-cutting is a technique used to cut materials into specific shapes. These machines are used primarily in post-printing processes and often work in conjunction with flexo printing machines. Die-cutting is widely used in packaging production, label cutting, and shaping paper, PVC, and various industrial products.

Cutting dies: Die-cutting machines utilize specially designed wooden or metal cutting dies to shape materials as desired. These dies are custom-made based on the material type and cutting design.

Cutting process: After placing the material on the cutting table, the machine applies the die to perform the desired cut. This ensures precise and clean results.

High precision: Die-cutting machines enable cutting of highly detailed and complex shapes, making them ideal for producing labels, boxes, packaging, paper products, and more.

Applications: Packaging production (especially boxes, cartons, PVC, plastic, and custom-shaped cuts), label cutting, metal and plastic industries, irregular-shaped products, and fashion industry (e.g., leather cutting).