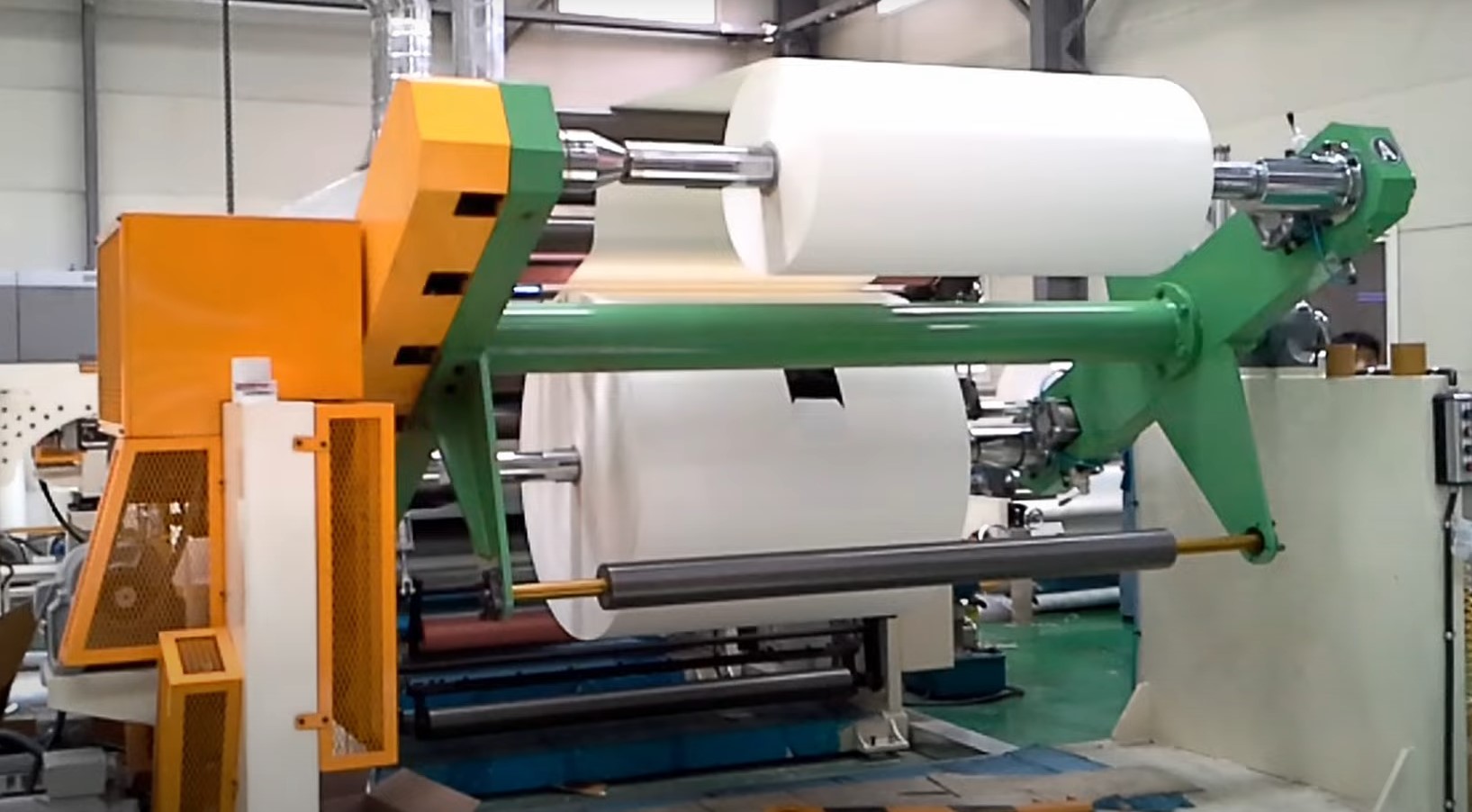

Máquina de revestimiento de polietileno por extrusión

Extrusion Polyethylene Coating Machine is a specialized machine that applies polyethylene (PE) coating material onto surfaces such as paper, plastic, or film using the extrusion method. These machines are widely used in industries requiring protective coatings, especially in the packaging sector. Since polyethylene is a waterproof, durable, and flexible material, these machines provide ideal solutions for food packaging, beverage cans, paper cups, protective coatings, and industrial products.

Our machine is manufactured in South Korea and is known for its strength, long service life, and high reliability in this sector.

Working Principle of the Extrusion Polyethylene Coating Machine

Material Preparation: Polyethylene granules or pellets are loaded into the feed hopper of the extrusion machine. These granules are melted at high temperatures, and the molten polyethylene is extruded through the die at the end of the extruder as a thin film layer.

Extrusion Process: Inside the extruder, polyethylene melts and is formed under high pressure into a film. During this process, the polyethylene filament or film is produced at a specific thickness, ready to be applied onto the coating surface.

Coating Application: The molten polyethylene film is applied by hot extrusion onto the surface of paper, plastic, or other materials. This coating process imparts flexible and waterproof properties to the material, ensuring food safety, protection, and durability.

Cooling and Hardening: After coating, the material is cooled using cooling rollers or air cooling systems. Cooling solidifies the polyethylene coating uniformly, providing the desired physical properties to the material.

Cutting and Shaping: After cooling, the coated material is cut, converted, or shaped into the desired sizes. Products are usually output in rolls or cut into specific dimensions. The cutting process can also be done automatically.

Automatic Control and Monitoring: Using digital control systems, machine parameters such as temperature, speed, and pressure are monitored and automatically adjusted. This helps maintain consistent product quality and reduces the risk of errors during production.

Features of the Extrusion Polyethylene Coating Machine

Polyethylene Coating: Thanks to polyethylene’s waterproofing, protective, and durable qualities, these machines are especially suitable for producing food packaging and beverage cans. The flexible coating protects materials from external factors.

High Efficiency: Capable of operating at high speeds, the machine processes large volumes of products per minute, making it highly advantageous for factories with high production demands.

Automatic Control and Monitoring: Digital control systems track every stage of the machine, adjusting parameters like temperature, speed, and pressure to ensure optimal operating conditions. Automatic fault diagnosis enables real-time performance monitoring and quick problem detection.

Flexible Production Options: Compatible with different materials, the machine can coat paper, plastic, and film surfaces with polyethylene. Coating thickness and surface properties can be customized to meet specific needs.

Low Cost and High Quality: Polyethylene coating offers an economical yet durable and effective solution. Products made with this machine have high-quality coatings and enhanced durability.

Advantages of the Extrusion Polyethylene Coating Machine

High Efficiency and Speed: Enables fast production and timely completion of large volume jobs. Automation increases production efficiency.

Wide Application Areas: Ideal for packaging industry (especially food and beverage packaging), paper cups, protective coating applications, and plastic products.

Low Cost: Polyethylene is a low-cost material, making production with this machine economically advantageous, especially for high volume manufacturing.

Environmentally Friendly Production: Polyethylene is recyclable, enabling eco-friendly production. The machine can also operate with energy-efficient designs.

Product Durability: Polyethylene coating enhances product durability and provides protection against external factors. Waterproof properties contribute to longer product lifespans.

Usage Areas of Produced Products

Packaging Sector: Used for waterproofing food packaging, beverage cans, paper cups, and other packaging materials. Protective coatings are applied to paper and plastic products.

Textile and Industrial Products: Polyethylene coating is applied for waterproof fabrics, protective coatings, and industrial materials.

Insulation Materials: Protects and enhances durability of products requiring thermal and water insulation.

Electronics Industry: Used for packaging and protective coatings of electronic products.

Pharmaceutical Industry: Preferred for packaging and chemical protection of pharmaceutical products.

Extrusion Polyethylene Coating Machine is a specialized machine that applies polyethylene (PE) coating material onto surfaces such as paper, plastic, or film using the extrusion method. These machines are widely used in industries requiring protective coatings, especially in the packaging sector. Since polyethylene is a waterproof, durable, and flexible material, these machines provide ideal solutions for food packaging, beverage cans, paper cups, protective coatings, and industrial products.

Our machine is manufactured in South Korea and is known for its strength, long service life, and high reliability in this sector.

Working Principle of the Extrusion Polyethylene Coating Machine

Material Preparation: Polyethylene granules or pellets are loaded into the feed hopper of the extrusion machine. These granules are melted at high temperatures, and the molten polyethylene is extruded through the die at the end of the extruder as a thin film layer.

Extrusion Process: Inside the extruder, polyethylene melts and is formed under high pressure into a film. During this process, the polyethylene filament or film is produced at a specific thickness, ready to be applied onto the coating surface.

Coating Application: The molten polyethylene film is applied by hot extrusion onto the surface of paper, plastic, or other materials. This coating process imparts flexible and waterproof properties to the material, ensuring food safety, protection, and durability.

Cooling and Hardening: After coating, the material is cooled using cooling rollers or air cooling systems. Cooling solidifies the polyethylene coating uniformly, providing the desired physical properties to the material.

Cutting and Shaping: After cooling, the coated material is cut, converted, or shaped into the desired sizes. Products are usually output in rolls or cut into specific dimensions. The cutting process can also be done automatically.

Automatic Control and Monitoring: Using digital control systems, machine parameters such as temperature, speed, and pressure are monitored and automatically adjusted. This helps maintain consistent product quality and reduces the risk of errors during production.

Features of the Extrusion Polyethylene Coating Machine

Polyethylene Coating: Thanks to polyethylene’s waterproofing, protective, and durable qualities, these machines are especially suitable for producing food packaging and beverage cans. The flexible coating protects materials from external factors.

High Efficiency: Capable of operating at high speeds, the machine processes large volumes of products per minute, making it highly advantageous for factories with high production demands.

Automatic Control and Monitoring: Digital control systems track every stage of the machine, adjusting parameters like temperature, speed, and pressure to ensure optimal operating conditions. Automatic fault diagnosis enables real-time performance monitoring and quick problem detection.

Flexible Production Options: Compatible with different materials, the machine can coat paper, plastic, and film surfaces with polyethylene. Coating thickness and surface properties can be customized to meet specific needs.

Low Cost and High Quality: Polyethylene coating offers an economical yet durable and effective solution. Products made with this machine have high-quality coatings and enhanced durability.

Advantages of the Extrusion Polyethylene Coating Machine

High Efficiency and Speed: Enables fast production and timely completion of large volume jobs. Automation increases production efficiency.

Wide Application Areas: Ideal for packaging industry (especially food and beverage packaging), paper cups, protective coating applications, and plastic products.

Low Cost: Polyethylene is a low-cost material, making production with this machine economically advantageous, especially for high volume manufacturing.

Environmentally Friendly Production: Polyethylene is recyclable, enabling eco-friendly production. The machine can also operate with energy-efficient designs.

Product Durability: Polyethylene coating enhances product durability and provides protection against external factors. Waterproof properties contribute to longer product lifespans.

Usage Areas of Produced Products

Packaging Sector: Used for waterproofing food packaging, beverage cans, paper cups, and other packaging materials. Protective coatings are applied to paper and plastic products.

Textile and Industrial Products: Polyethylene coating is applied for waterproof fabrics, protective coatings, and industrial materials.

Insulation Materials: Protects and enhances durability of products requiring thermal and water insulation.

Electronics Industry: Used for packaging and protective coatings of electronic products.

Pharmaceutical Industry: Preferred for packaging and chemical protection of pharmaceutical products.