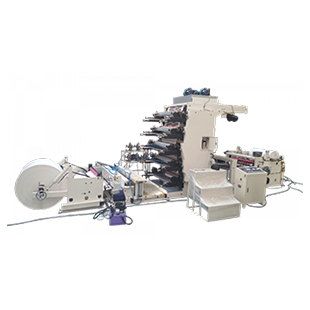

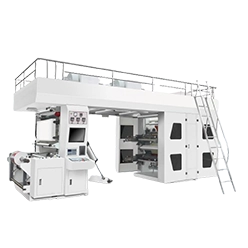

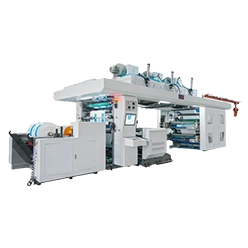

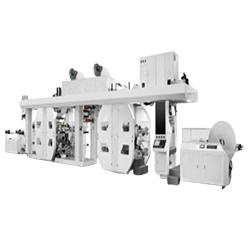

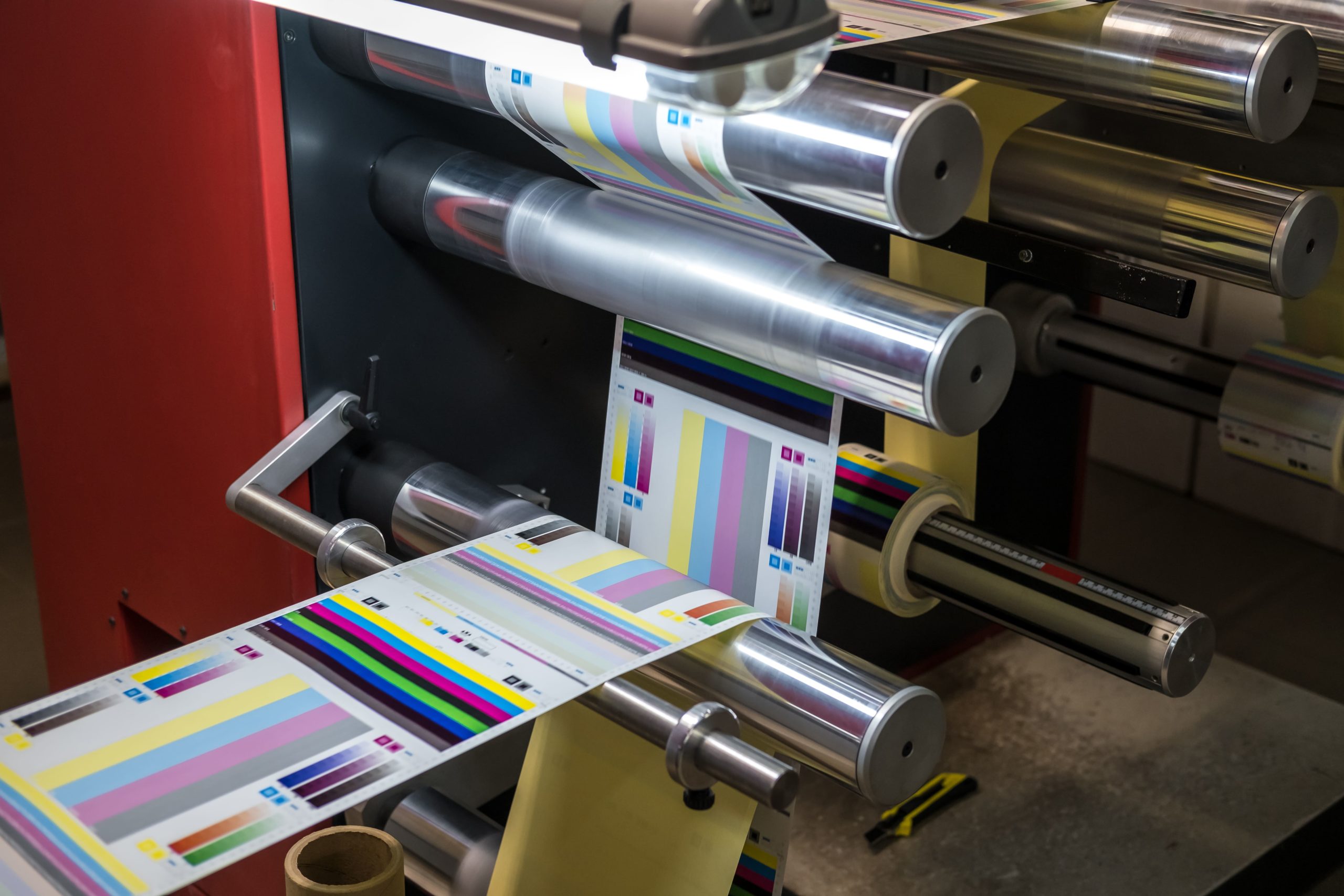

Rotogravure Printing Machine

Rotogravure Printing Machine is a machine used for high-volume, high-quality printing jobs that operates using the rotogravure printing technique. This technology is especially preferred for long print runs and large production series. Rotogravure printing uses deeply engraved plates and delivers very detailed results, sharp colors, and high resolution.

Gravure Printing Technology: Rotogravure printing transfers ink through engraved cells on a printing cylinder. Ink is applied to the cylinder, and then the cylinder’s surface transfers the image onto substrates such as paper, plastic film, or foil. This process reproduces fine details very accurately.

Depth and Precision: The engraving depth of the cells on the printing plate controls the amount of ink released, enabling different colors and tonal variations. This depth allows very fine details, shadows, and subtle tones to be printed correctly.

Printing Cylinder: The core component of the rotogravure printing machine is the printing cylinder, which transfers ink from its engraved cells. The cylinder’s surface contains microscopic engravings of images or text. Ink fills these cells and is then transferred to the substrate.

Ink Application: The printing cylinder is submerged in an ink bath, and a doctor blade or a squeegee removes excess ink from the cylinder’s surface. Only the ink residing in the engraved cells is transferred onto the substrate.

Substrate: The substrate is wrapped around the cylinder, and ink is transferred onto it. This printing process usually runs at high speed and with high precision.

Advantages of Rotogravure Machines

High Print Quality: Rotogravure printing offers an excellent solution for jobs requiring large solid color areas, vivid colors, and fine details. Therefore, it is preferred in industries with high quality expectations.

Continuous Print Speed: Rotogravure machines can print at very high speeds, making them ideal for large print runs and mass production.

Long-Lasting Use: Rotogravure cylinders are suitable for long print runs. The durability of the cylinders makes them well-suited for high-volume and long-life printing projects.

Wide Substrate Compatibility: Offers the flexibility to print on various materials such as plastic film, paper, and aluminum foil.

Applications of the Machine

Rotogravure printing machines are commonly used in the following areas:

Flexible Packaging: Used to print on flexible substrates for food packaging, beverage packaging, and cosmetic packaging.

Newspaper and Magazine Printing: Particularly preferred for high-quality color printing in magazines and newspapers.

Label Printing: Suitable for high-resolution label printing.

Industrial Printing: Used to print on durable materials such as plastic films and aluminum foils.

Machine Structure and Components

A Rotogravure Printing Machine consists of the following components:

Printing Cylinder: The main cylinder containing engraved cells for the gravure process.

Ink Unit: The system that applies ink to the cylinder and removes excess ink from the surface.

Drying System: Systems used to quickly dry the ink after printing, including hot air blowers or UV curing units.

Control System: Computer-aided systems that monitor and optimize the printing process.

Considerations

Initial Cost: Rotogravure machines can have high upfront costs. However, they can be cost-effective for long print runs and large volumes.

Cylinder Preparation: The production and preparation of gravure cylinders can be more expensive compared to other printing methods. Cylinder engraving also takes time.

Flexibility: While rotogravure machines handle many substrates, plate changes and design flexibility may be somewhat limited compared to other printing technologies.