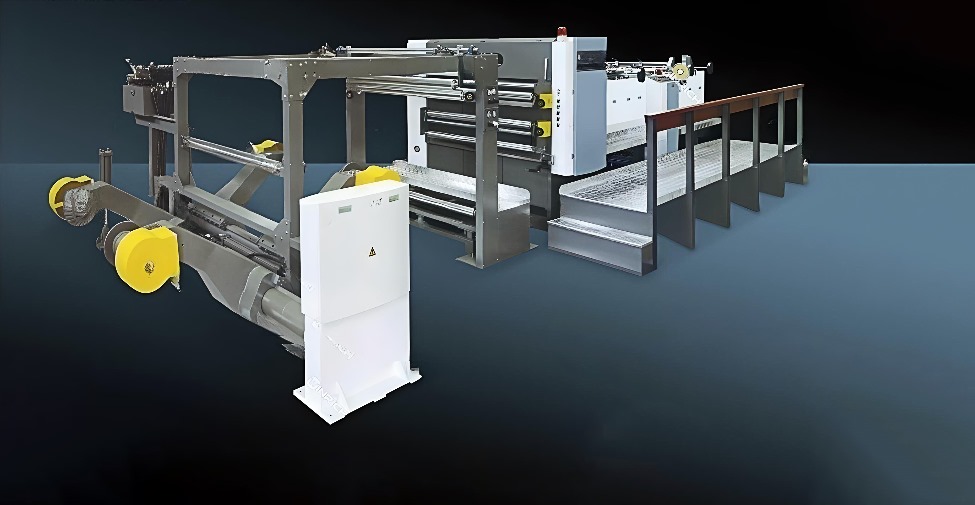

Paper Coil Slitting And Rewinding Machine

Paper roll slitting and rewinding machine is an industrial machine used to slit large paper rolls into smaller sizes and rewind them to produce paper rolls of desired length, width, and diameter. It is commonly used in paper mills, printing facilities, and the packaging industry. Our machine is suitable for cutting and rewinding all kinds of rolled materials such as plastic films for printing and packaging, paper, fabric, laminated paper, coated paper, synthetic leather, and similar materials.

It features high precision and ease of use, utilizing adjustable rotary slitting blades for slitting. Air shafts are used for independent rewinding. It offers easy setup, removal, installation, and operation. The air shafts provide convenience for unwinding and rewinding with automatic tension control, ensuring neatly and compactly rewound finished products. The feed support includes automatic pneumatic pressure lifting. There is an automatic waste discharge system for waste materials. The machine includes features such as automatic tension control, automatic touch screen control, hydraulic pressure alignment device, automatic counting function, stop-on-alarm, and a digital display for tension control. Dual servo motors control the rewind shafts.

Working principle of the paper roll slitting and rewinding machine

Slitting: Large paper rolls are divided into smaller widths and diameters as desired. This process is carried out using cutting blades or bladed systems. Depending on slitting precision, the edges of the paper are cut cleanly.

Rewinding: The slit paper is rewound. This process ensures the paper rolls are wound neatly, making them easier to transport, store, or package for later use. This step is performed using rewinding mechanisms.

Speed and Precision: This machine is capable of operating at high speeds while delivering precise slitting, ensuring efficient paper production with minimal waste.

Automation and Control: It is equipped with advanced control systems that allow the automatic control of parameters such as slitting width, rewinding speed, and printing operations.

| Machine Model | KBSR-1100A | KBSR-1300A | KBSR-1600A |

| Maximum Decoiler Coil Diameter | 1400mm | 1400mm | 1400mm |

| Minimum Slitting width | 1000mm | 1200mm | 1500mm |

| Maximum Rewind Diameter | 1000mm | 1000mm | 1000mm |

| Minimum Winding Width | 30mm | 30mm | 30mm |

| Slitting Speed (Slitting Speed) | 10-150 m/dak | 10-150 m/dak | 10-150 m/dak |

| Slitting Precision | ±0.3mm | ±0.3mm | ±0.3mm |

| Total Power | 10kw | 11kw | 12kw |

| Electric (Electrical) | 380V/50Hz (Three phase) | 380V/50Hz (Three phase) | 380V/50Hz (Three phase) |

| Air Pressure Source Requirement | Max. 5.5kg/cm² x 0.5m³/dak | Max. 5.5kg/cm² x 0.5m³/dak | Max. 5.5kg/cm² x 0.5m³/dak |

| Machine Weight | Approx. 2800kg | Approx. 3000kg | Approximately 3300kg |

| Machine Size | 3800 × 2500 × 1800mm | 3800 × 2800 × 1800mm | 3800 × 3100 × 1800mm |