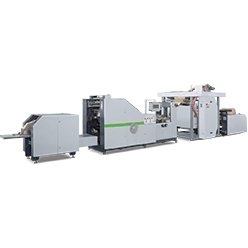

Paper Bag Machine with V-Base Printing Unit

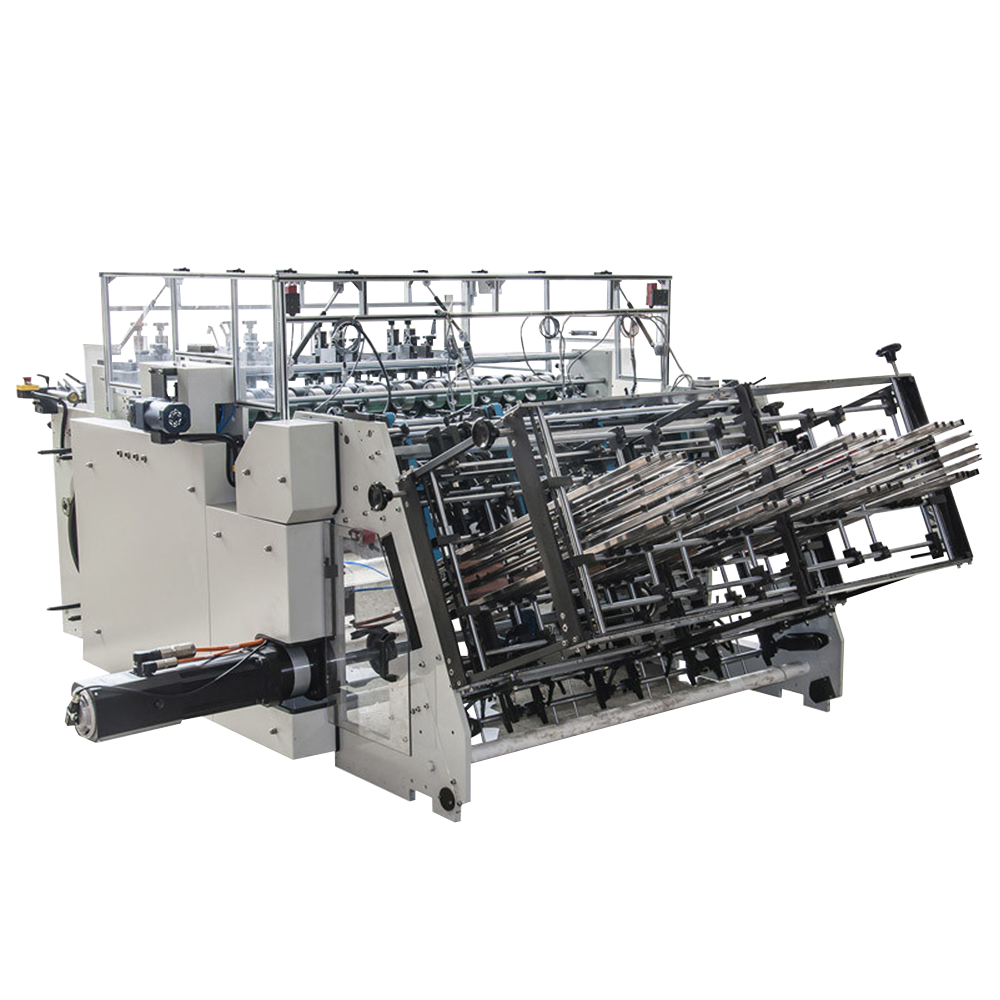

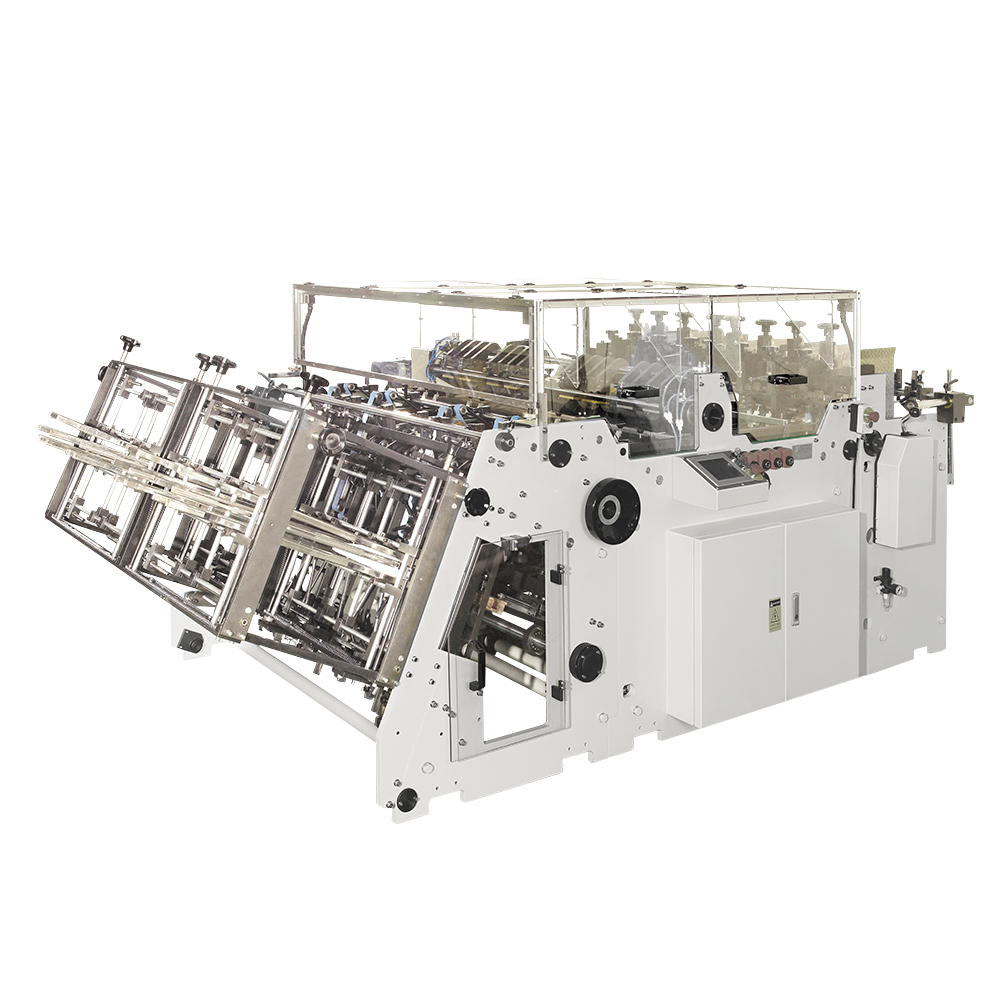

V-Bottom Flexo Printing Unit Paper Bag Machine is designed for automatic production of paper bags and flat-bottom bags from rolls of white kraft, brown kraft, sulfite paper, greaseproof paper, food-grade papers, and white unbleached papers using a flexographic printing system. The machine performs automatic central gluing, print registration, folding, fixed-length cutting, bottom gusseting, bottom folding, bottom gluing, bag bottom forming, and bag collection all in one continuous operation. Motion control is managed by servo motors, making the system easy to operate, efficient, and reliable. The V-bottom paper bags produced by this machine are suitable for bread bags, food bags, shopping bags, and various eco-friendly paper bags of different specifications and sizes. Equipped with a printing system, the machine can print up to 4 colors. The printing unit includes an anilox roller and a Dr. Blade doctor blade for automatic ink transfer as standard. A camera registration system can be added if desired.

The square bottom printing unit paper bag machine is commonly used for food packaging, carrier bags, and other packaging applications. It is designed to produce V-bottom paper bags, integrating printing, folding, and cutting processes.

Features and Operation of V-Bottom Printing Unit Paper Bag Machine

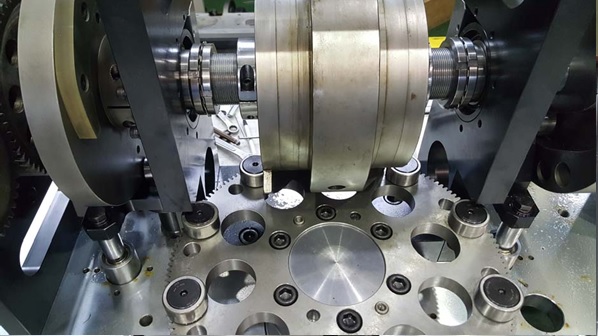

Printing Unit: This machine employs flexographic printing technology. The printing unit produces high-quality color prints on the paper surface, typically handling designs consisting of two or more colors. The machine comes standard with a Dr. Blade doctor blade, anilox printing cylinder, and automatic ink pump. Flexo printing technology is well-known for delivering high print quality and consistent color application across a wide range of colors.

Paper Feeding System: The machine uses paper rolls which are smoothly fed into the system. The paper is unwound and shaped into the desired bag form.

V-Bottom Formation: The paper’s bottom is accurately cut and folded to form a V-shaped gusset. This ensures a neat and sturdy closure for the bag’s bottom. After bottom forming, the edges are glued securely.

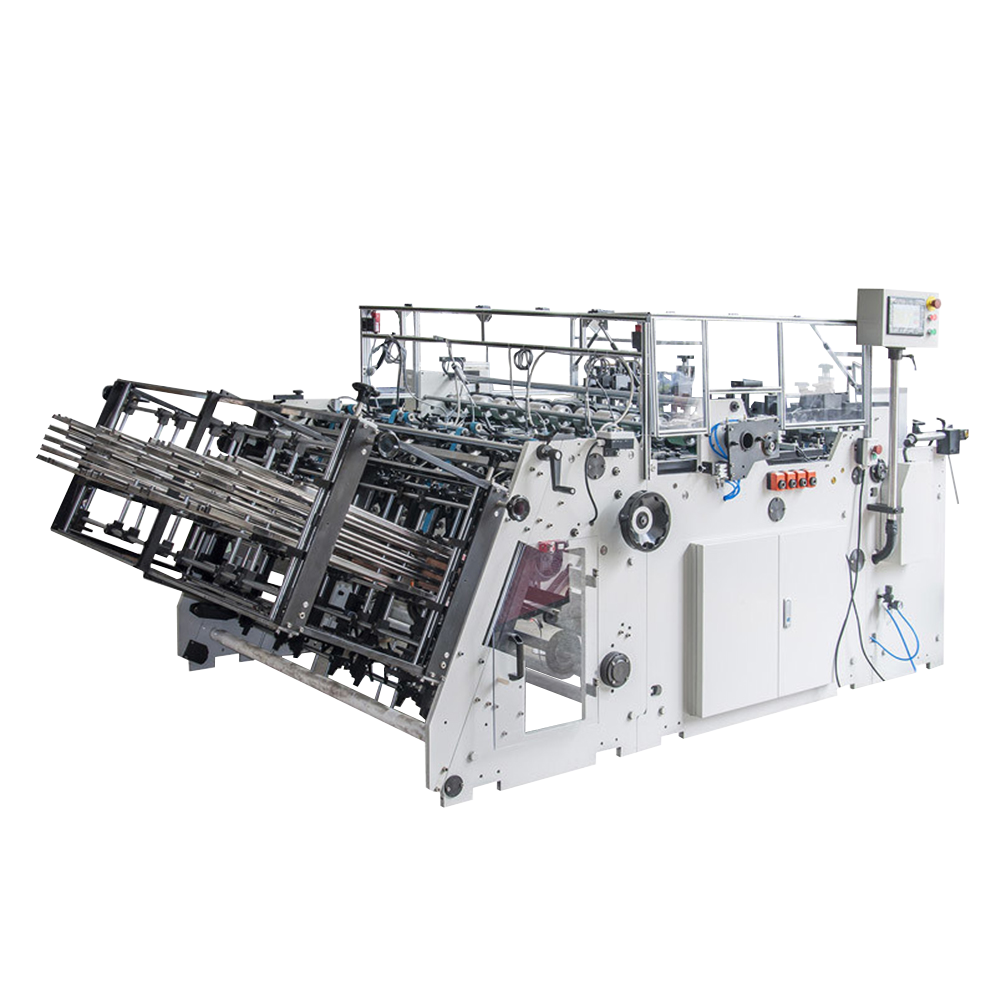

Cutting Unit: The paper is cut to the desired bag length. These machines can operate at high speeds, producing up to 700 bags per minute.

Speed and Efficiency: Equipped with automatic speed adjustment and a user-friendly PLC touchscreen interface, the machine allows easy control of production speed and product settings.

Various Size Options: This machine can manufacture paper bags in different sizes, with easy size adjustments during production.

Applications of V-Bottom Paper Bag Production Machine

Food Packaging: Particularly suitable for bread, coffee, flour, rice, and other food products.

Retail and Shopping Bags: Used as shopping or carrier bags by consumers.

Custom Printing: Printed bags can be used for advertising and promotional purposes.

Various Packaging: Also used for packaging textiles, books, and other industrial products.

| Model | KAIF-350V | KAIF-250V |

| Bag making speed | 50-700 pcs/min | 50-600 pcs/min |

| Maximum linear speed | 120m/min | 90m/min |

| Paper bag length (L) | 155-715mm | 110-450mm |

| Paper bag width (W) | 70-350mm | 70-250mm |

| Size of material that can fit inside (WS) | 20-120mm | 20-120mm |

| Bag mouth height (S) | 15/20mm | 15/20mm |

| Paper thickness | 35-80g/m2 | 35-80g/m2 |

| Paper roll width | 100-960mm | 100-760mm |

| Coil roll diameter | 200-1000mm | 200-1000mm |

| Coil inner diameter | 76mm | 76mm |

| Film width | 50-240mm | 50-240mm |

| Film thickness | 0.012-0.037mm | 0.012-0.037mm |

| Film material | OPP/PET | OPP/PET |

| Film diameter | 500mm | 500mm |

| Inner diameter of the film | 76mm | 76mm |

| Total power | 20KW | 10KW |

| Air needs | >0.12m3/min 0.6MPa | >0.12m2/min 0.6MPa |

| Machine weight | 6500kg | 4500kg |

| Machine size | L7500×W2300×H1800mm | L6800×W1600×H1600mm |