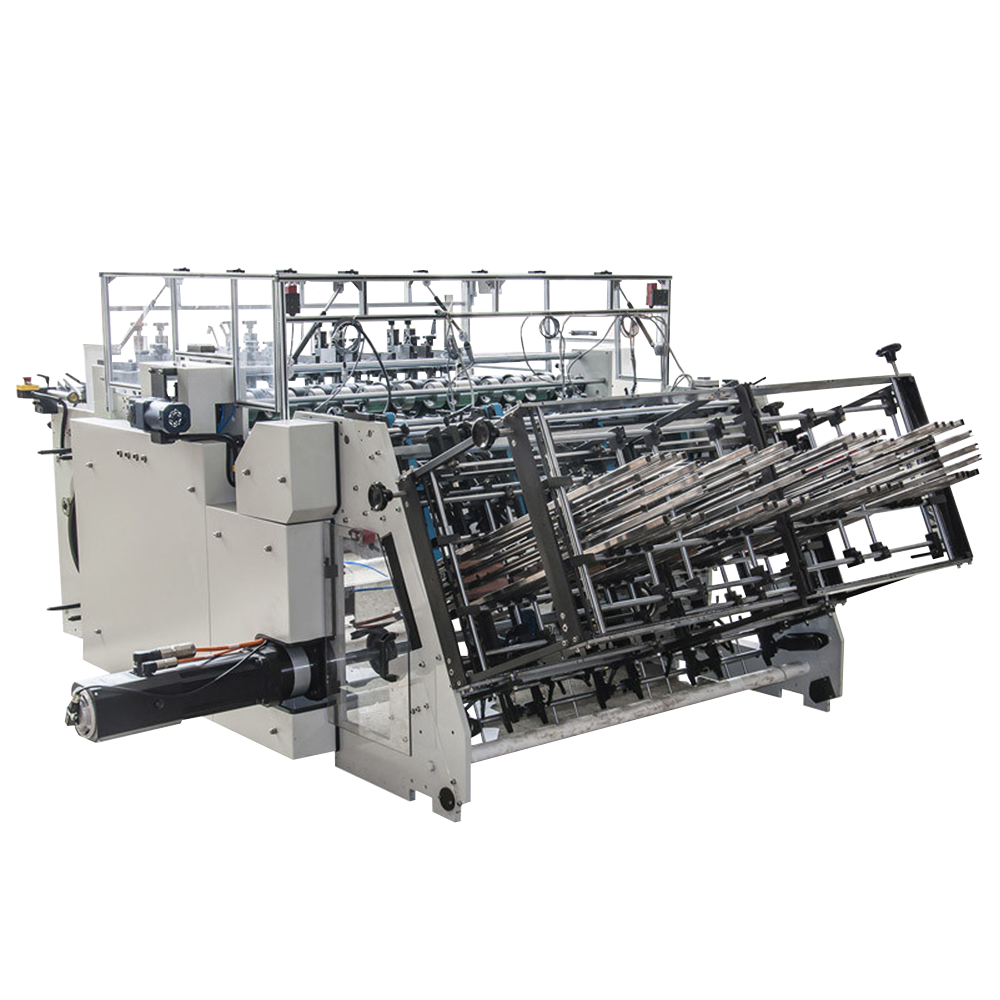

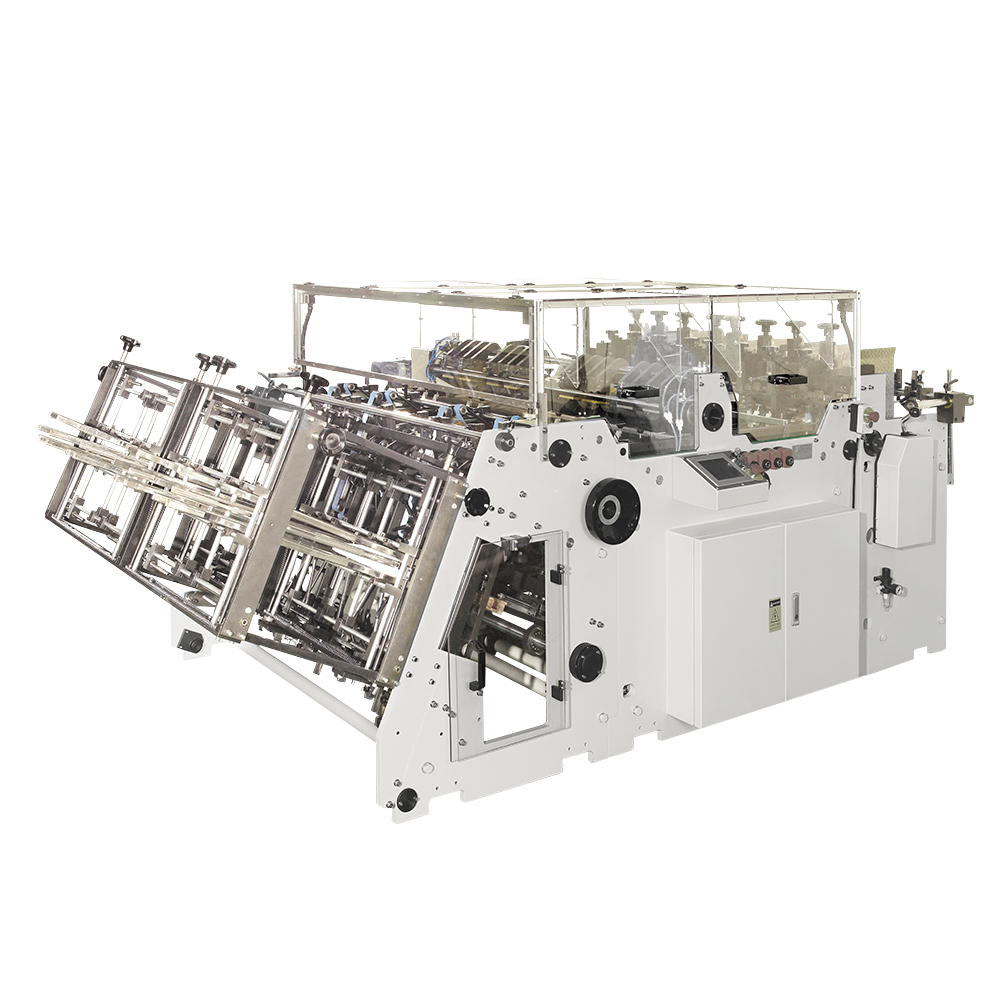

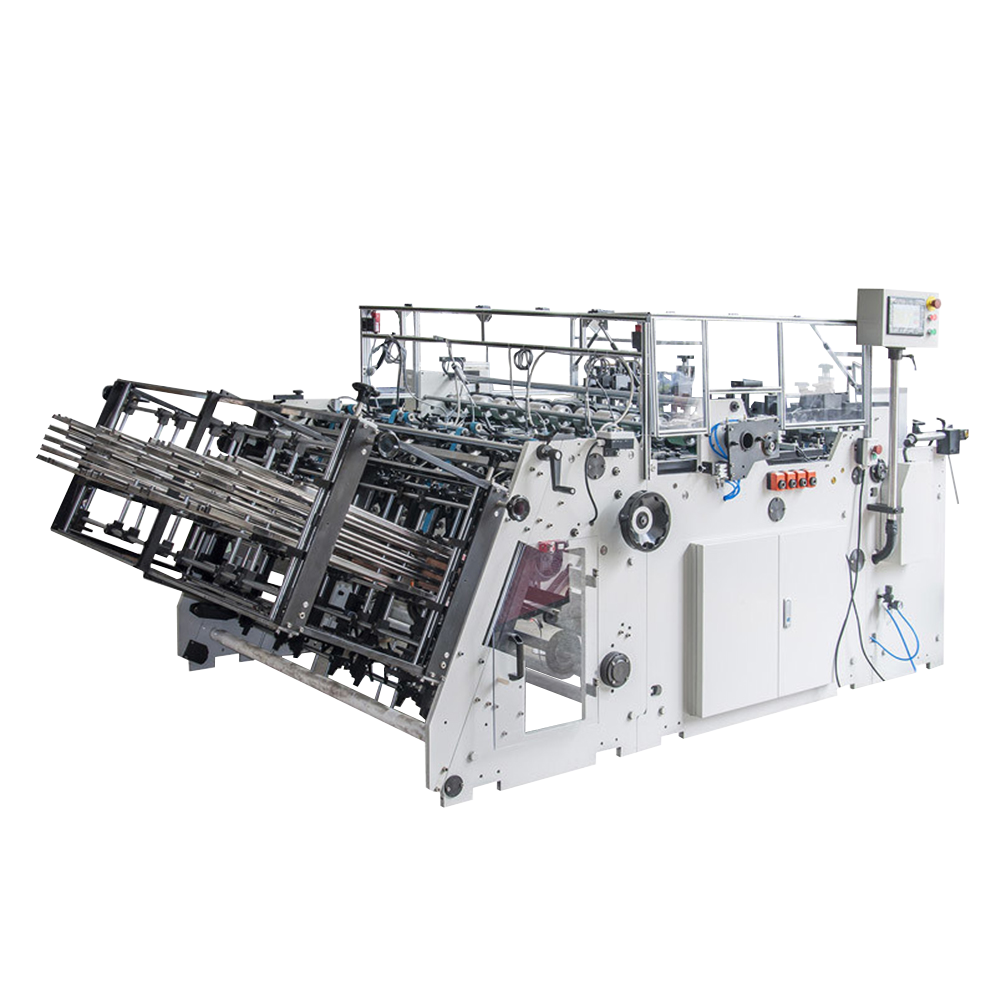

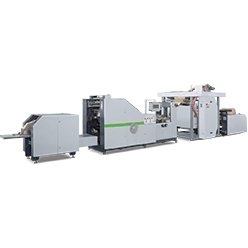

Paper Bag Machine with Square Bottom Printing Unit

Square Bottom Printing Unit Paper Bag Machine is designed for automatic production of paper bags and flat-bottom paper bags from brown kraft, white kraft, food-grade papers, and white unbleached papers supplied in roll form. The machine features a printing unit and performs automatic central gluing, print registration, material folding, fixed-length cutting, bottom gusseting, bottom folding, bottom gluing, bag bottom forming, and bag collection operations in one continuous process. Motion control is achieved with servo motors, ensuring an easy-to-operate system that delivers efficient and stable production. Our square bottom paper bag machine can produce various sizes and types of paper bags such as bread bags, food bags, shopping bags, and other environmentally friendly paper bags. The printing unit comes equipped with anilox rollers and automatic ink transfer as standard; a camera registration system can be added upon request.

The square bottom paper bag production machine is widely used for food packaging, carrier bags, and other packaging applications. It is designed to manufacture square bottom paper bags incorporating both printing and cutting processes.

What is a Square Bottom Paper Bag?

A square bottom paper bag is a type of paper bag with a flat, rectangular bottom, commonly used for carrying various products such as food or shopping items. These bags are frequently preferred for grocery bags or food packaging applications.

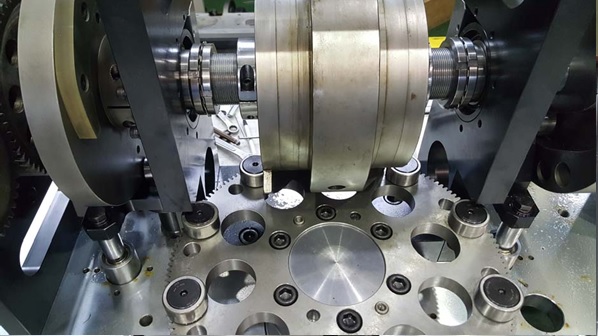

Printing Technology: The machine uses flexographic printing technology. The printing unit applies high-quality, multi-color prints onto the paper surface. Printing designs typically involve two or more colors. Flexo printing ensures high print quality and allows smooth and vivid designs with various colors.

Paper Feeding and Forming System: The machine unwinds paper from rolls and feeds it smoothly into the production line. It shapes the paper into the square bottom bag form by accurately cutting and folding the bottom to create a sturdy, rectangular base. After bottom forming, the edges are glued using food-safe adhesives. Finally, the paper is cut to the desired bag length.

Our machines operate at high speeds, enabling large-scale production. They feature automatic speed adjustment and an intelligent control panel to facilitate easy operation and precise production control.

With this machine, you can manufacture square bottom paper bags in various sizes.

Applications of Square Bottom Paper Bag Production Machine

Food Packaging: Especially suitable for bread, coffee, flour, rice, and similar food products.

Retail and Shopping Bags: Can be used as shopping or carrier bags.

Advertising and Promotional Products: Custom printed bags can be used in marketing and promotions.

Various Packaging: Suitable for packaging textiles, books, and other industrial products.

| Model | KAI-190F | KAI-330F | KAI-450F | KAI-450BF | KAI-550F |

| Cut length | 190-370mm | 260-530mm | 260-530mm | 360-800mm | 360-800mm |

| Paper bag width | 80-190mm | 130-330mm | 150-450mm | 220-450mm | 220-550mm |

| Paper bag base width | 50-100mm | 70-180mm | 70-180mm | 100-250mm | 100-250mm |

| Paper thickness | 45-120g/m2 | 60-160g/m2 | 60-160g/m2 | 80-160g/m2 | 80-160g/m2 |

| Paper roll width | 290-610mm | 430-1050mm | 570-1290mm | 670-1430mm | 670-1630mm |

| Maximum paper roll diameter | 1200mm | 1200mm | 1200mm | 1200mm | 1200mm |

| Paper roll inner diameter | 76mm | 76mm | 76mm | 76mm | 76mm |

| Power | 11kw | 8kw | 8kw | 15kw | 15kw |

| Machine speed | 30-200pcs/min | 60-200pcs/min | 60-180pcs/min | 30-120pcs/min | 30-100pcs/min |

| Air supply | >0.12m3/min 0.6MPa | >0.12m3/min 0.6MPa | >0.12m3/min 0.6MPa | >0.12m3/min 0.6MPa | >0.12m3/min 0.6MPa |

| Machine weight | 6500 kg | 10.500 kg | 12000 kg | 14.000 kg | 16.000 kg |

| Machine dimensions (L×W×H) | 9400×2600×2500mm | 11400×2600×2500mm | 11600×2950×2500mm | 13000×3400×2950mm | 13200×3400×2500mm |