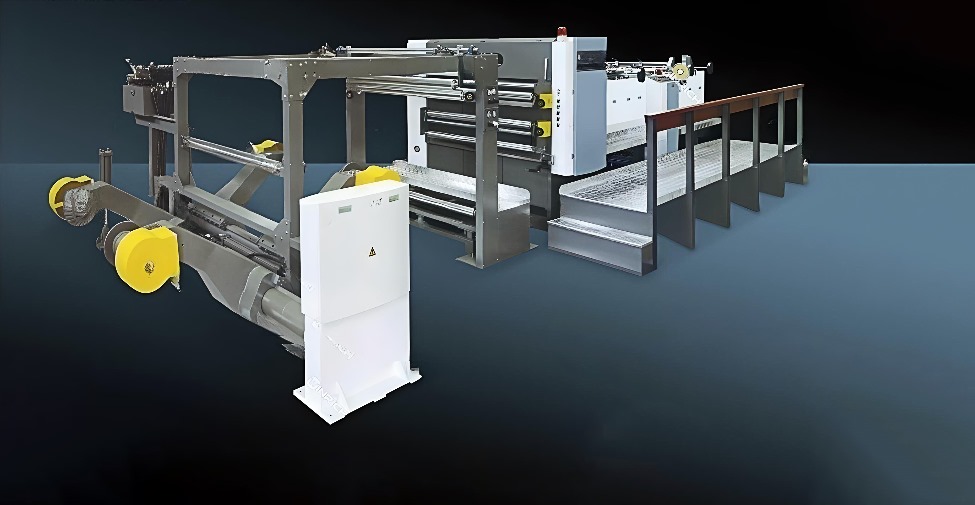

High Speed Paper Coil Slitting and Rewinding Machine

High-Speed Paper Roll Slitting and Rewinding Machine is a machine used in the paper production industry and packaging sector to cut large paper rolls into smaller sections and tightly rewind them. This machine is designed to speed up production processes, increase efficiency, and deliver high-quality products. Featuring high precision and ease of use, the machine utilizes adjustable circular blades for the cutting process. Independent air shafts are used for unwinding and rewinding, ensuring easy automatic loading and unloading. Air shafts, equipped with automatic tension control, enable compact and orderly rewinding of finished products. The machine operates with a shaftless elevator feeding system and an automatic hydraulic system. Additionally, an automatic waste paper discharge system is integrated into the machine.

The machine includes frequency speed control, microcomputer PLC control, a photoelectric correction device with automatic meter counting, an alarm-based auto-stop system, and a digital display for tension control as standard features. It is suitable for cutting, slitting, and rewinding large rolls of materials such as plastic films, paper, fabric, laminated paper, coated paper, synthetic leather, and other paper-plastic composite materials.

Features and Advantages of the High-Speed Paper Roll Slitting and Rewinding Machine

High Speed: The machine operates at high speeds, quickly slitting and rewinding large paper rolls. It runs at 350 meters per minute, significantly increasing production capacity.

Precision Slitting: The machine slices paper rolls into thin, precise sections, ensuring high quality and tailored dimensions according to customer demands.

Automatic Rewinding System: The slit paper sections are automatically rewound neatly, minimizing manual intervention and reducing labor costs.

Flexible Adjustment Options: Users can easily adjust the machine according to the paper type and desired dimensions, making it adaptable to different paper varieties and thicknesses.

High Efficiency: Operating at high speeds enhances daily production output, making it highly advantageous for large-scale manufacturers requiring substantial production capacity.

Advanced Technology and Automation: Equipped with PLC (Programmable Logic Controller) systems, the machine functions efficiently and at desired speeds while maintaining quality standards.

Low Labor Requirement: The high-speed paper roll slitting machine is automated, enabling large-scale production with minimal workforce involvement.

Applications of the High-Speed Paper Roll Slitting and Rewinding Machine

Paper Production: Transforming large paper rolls into smaller, market-ready pieces.

Packaging Industry: Used in packaging where papers need to be cut and rewound into specific dimensions.

Printing Industry: Slitting paper rolls into dimensions suitable for printing machines.

| Model | KHSPSR-1100 | KHSPSR-1300 | KHSPSR-1600 |

| Maximum Unwinding Diameter | 1600mm | 1600mm | 1600mm |

| Maximum Slitting Width | 1000mm | 1200mm | 1500mm |

| Maximum Rewinding Diameter | 1500mm | 1500mm | 1500mm |

| Minimum Rewinding Width | 30mm | 30mm | 30mm |

| Slitting Speed | 10-350 m/min | 10-350 m/min | 10-350 m/min |

| Slitting Accuracy | ±0.2mm | ±0.2mm | ±0.2mm |

| Total Power | 25kw | 28kw | 35kw |

| Electricity | 380V/50Hz (Three-phase) | 380V/50Hz (Three-phase) | 380V/50Hz (Three-phase) |

| Air Pressure Supply Requirement | Max. 5.5kg/cm² x 0.5m³/min | Max. 5.5kg/cm² x 0.5m³/min | Max. 5.5kg/cm² x 0.5m³/min |

| Machine Weight | Approx. 10500kg | Approx. 11000kg | Approx. 11800kg |

| Machine Dimensions | 9000 × 3550 × 2510mm | 9000 × 3750 × 2510mm | 9000 × 4050 × 2510mm |