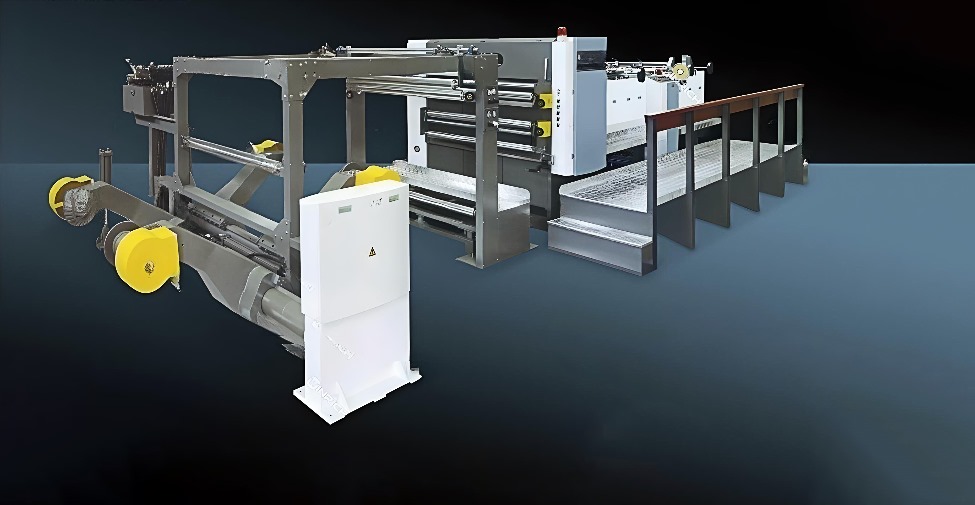

Floor Wrapping Paper Slitting and Rewinding Machine

Jumbo roll slitting and rewinding machine is one of our industrial machines designed for slitting and rewinding large-sized

paper, plastic, or similar materials from jumbo rolls into desired sizes. This machine is typically used in the paper, construction, packaging, and other industrial sectors. It is suitable for cutting and rewinding jumbo paper rolls. Equipped with a rotary blade slitting system, automatic hydraulic shaftless feeding, photoelectric tension control monitoring, photoelectric detector, electric load control, frequency control, length setting unit, automatic counter, sound control alarm, servo motor, and PLC control. The machine also features an automatic discharge system.

Main Features of the Jumbo Roll Slitting and Rewinding Machine

Processing Large Rolls: Jumbo rolls are typically very large in diameter and heavy in weight. These machines are capable of handling large rolls (usually heavier than 1000 kg).

Slitting: The machine slits large rolls into the desired widths. The slitting process requires high precision, as each slit must be of uniform thickness and smooth. This step is essential for enabling the rolls to be used in different applications.

Rewinding: The slit paper or other materials are rewound onto rolls neatly. Rewinding allows the material to be transported and stored without damage. Additionally, tight and uniform rewinding is important during this process.

Automatic Control and Adjustment Systems: Modern jumbo roll slitting and rewinding machines include systems that automatically control production speed,

cutting quality, rewinding tightness, and other parameters. This enables more efficient production and a lower error rate.

High Capacity: This machine is designed to meet large-scale production demands. It can operate at high speed and produce a large number of rolls.

Floor Rewinding Feature: Specifically designed for rewinding heavy and large rolls starting from the floor. This is important for occupational safety and allows workers to operate more efficiently.

Advanced Safety Features: As our machine operates at high speed, various safety measures (emergency stop buttons, safety shields, etc.) are included to ensure operator safety.

Applications of the Jumbo Roll Slitting and Rewinding Machine

Plastic and Rubber: Slitting and rewinding of plastic films or rubber materials.

Packaging Industry: Production of paper packaging materials and film rolls.

Electronics Industry: Rewinding thin materials for electronic components.

Advantages of the Jumbo Roll Slitting and Rewinding Machine

High Efficiency: Fast and uninterrupted production with automated systems.

Low Waste Rate: Reduced material loss thanks to precise slitting.

Flexibility: Adaptable to different material types and roll sizes.

Advanced Quality Control: Continuous monitoring of production quality via automatic control systems.

| Machine Feature | 1100 mm ve 2100 mm |

| Model | KJRSR-1100-2100 |

| Slitting Speed | 0-300 m/dak |

| Slitting Width | 1000-2000mm |

| Unwinding Diameter | Ф1600mm |

| Cutting Accuracy | ±0.3mm |

| Rewinding Diameter | Ф1600mm |

| Paper Thickness | 50-480gsm |