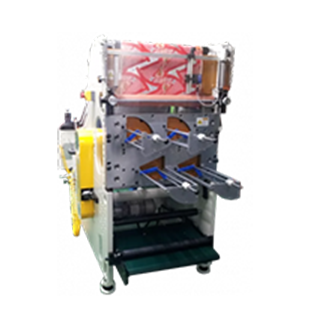

Die Cutting Machine from Coil

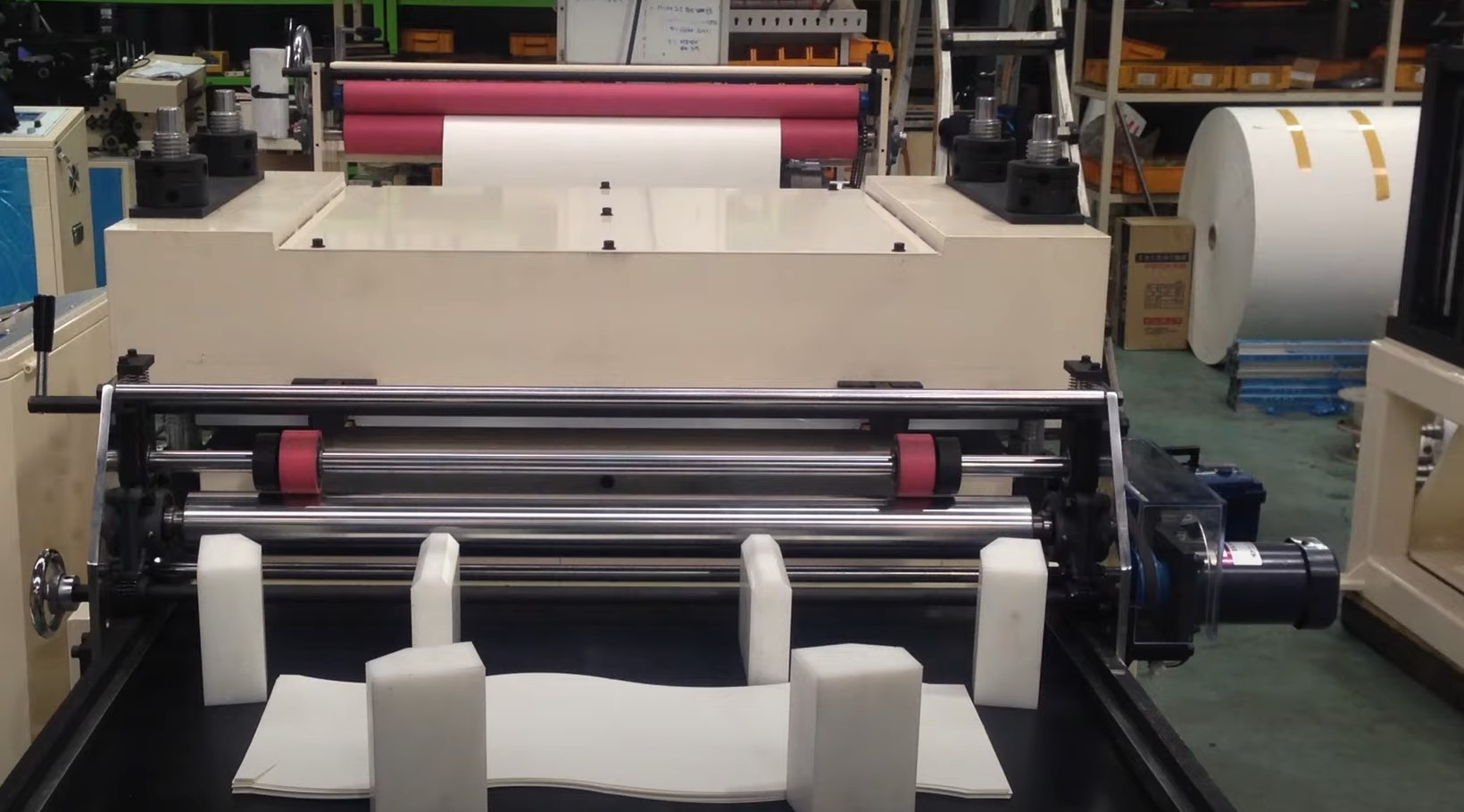

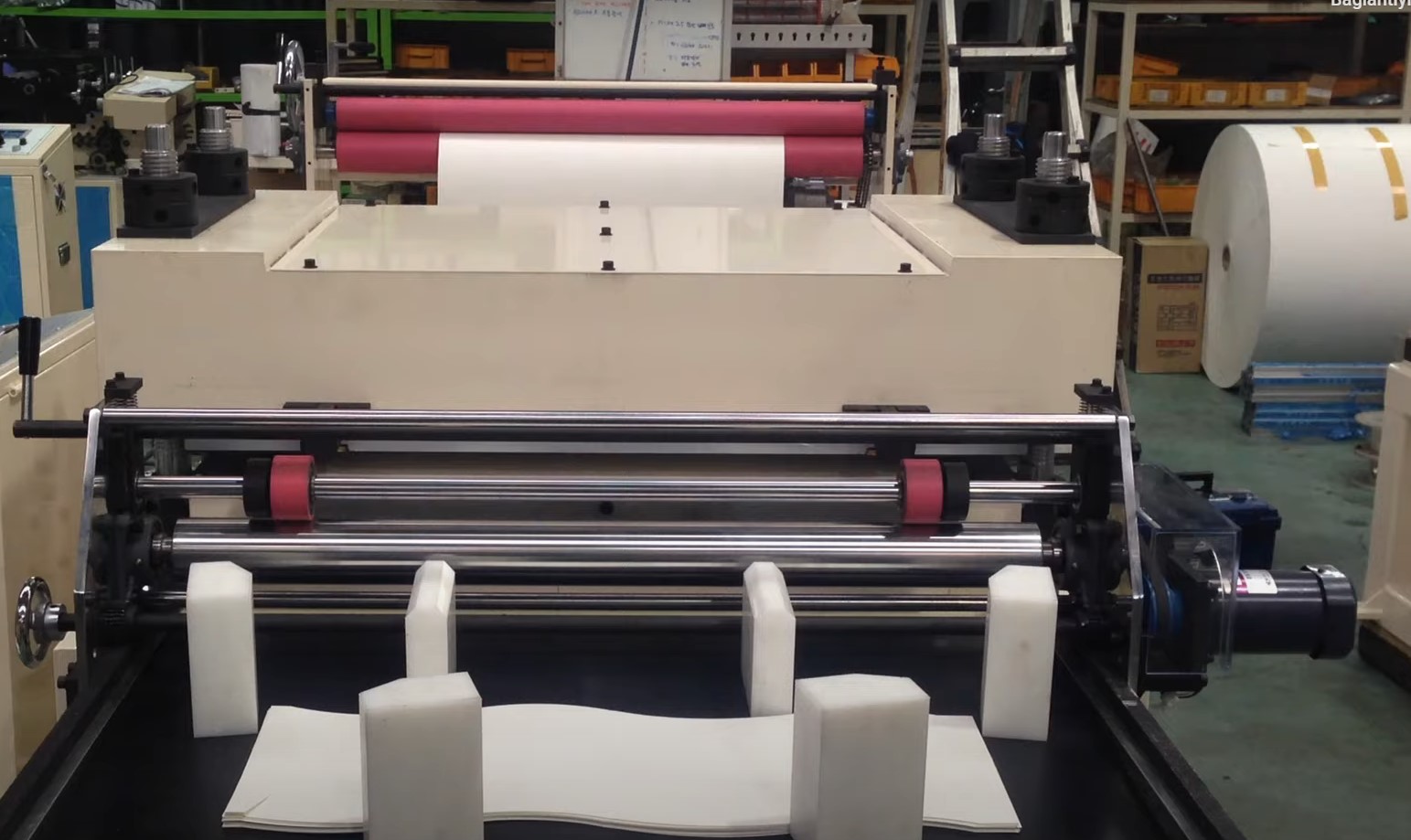

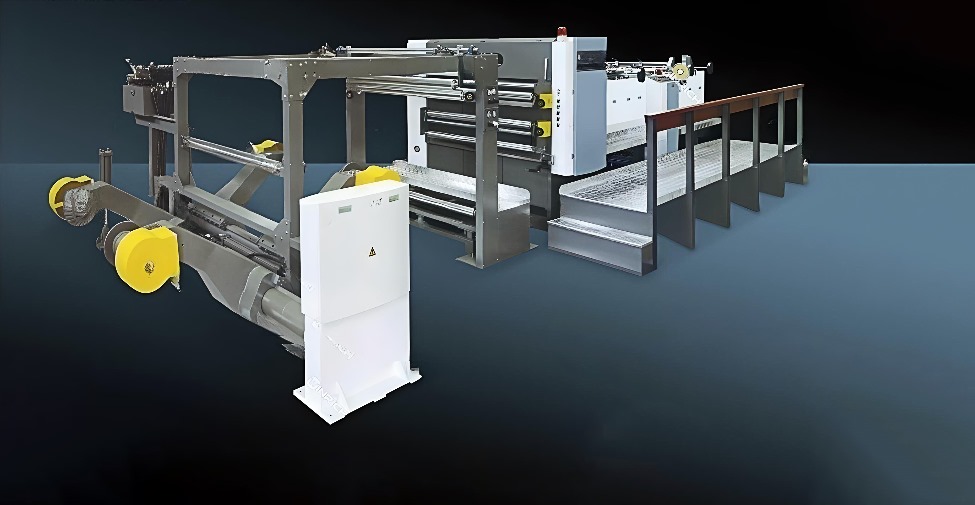

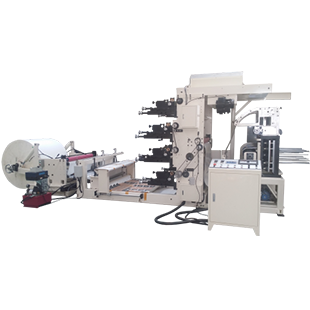

Roll-Fed Die-Cutting Paper Machine is a machine that performs cutting processes on rolled products such as paper, plastic, and PVC sheets into various sizes. This machine uses a die-cut wooden blade system to cut, punch, shape, or create patterns on large paper rolls in desired shapes and sizes. It has a high-speed capacity for processing large quantities of paper.

Our machine is manufactured in South Korea. It is powerful and long-lasting, easy to maintain, and energy-efficient.

Working Principle of Roll-Fed Paper Cutting Machine

Paper Roll Feeding: The paper roll is fed into the machine, and the cutting process is performed on these rolls. Proper feeding of the paper directly affects the cutting quality.

Cutting: The machine uses printing blades mounted on wood to cut specific shapes or patterns. The die-cuts shape the paper by cutting designated areas. The dies used for cutting are specially designed for each product and every cutting operation is performed using these dies. Cutting occurs by a pressing method applying high pressure.

Usage Areas of Paper Cutting Machine

Packaging Industry: Used for cutting materials like paper, cardboard, and kraft paper into desired shapes. Examples include box production, labels, label cutting, and various packaging types.

Office Supplies Production: Paper cutting is used to produce office materials such as business cards, certificates, and invitations.

Industrial Products: Roll-fed paper cutting machines can also be used for labeling and marking industrial products, such as marking on production lines.

Graphic Design: Used in graphic design and printing industries to create paper cuts in specific shapes and patterns.

Paper Plate and Cup Production: Can be used to shape paper for producing paper plates, cups, or other packaging types.

Advantages of Roll-Fed Die-Cutting Paper Machine

High Efficiency: Enables fast and continuous production through automated processing.

Various Cutting Methods: Offers flexibility to cut desired shapes and patterns.

Cost-Effective Production: Large volume production reduces costs.

High Precision: Cuts are extremely precise and clean, improving product quality.

| Machine Code | Production Speed | Cutting Material | Electricity Consumption | Cutting Range | Machine Dimensions | Machine Weight |

| KRD-80 | 80 beats/minute | Paper-PVC roll | 5-8 kw | 850×600 mm | 3,500(U) x 1,500(G) x 1,500(Y) (mm) | 3.000 kg |