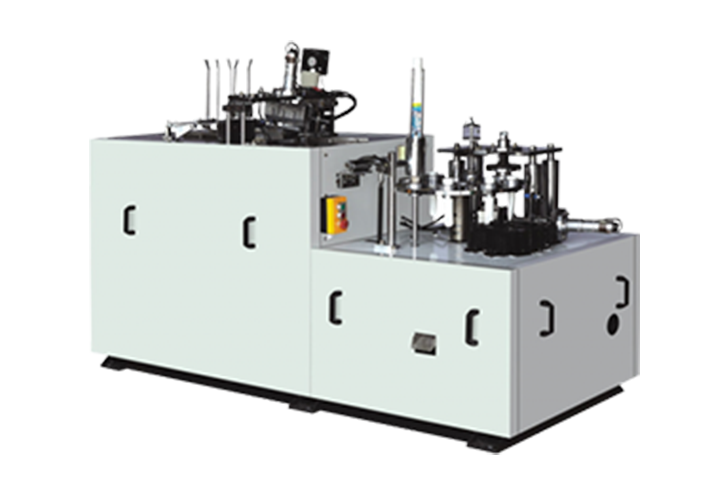

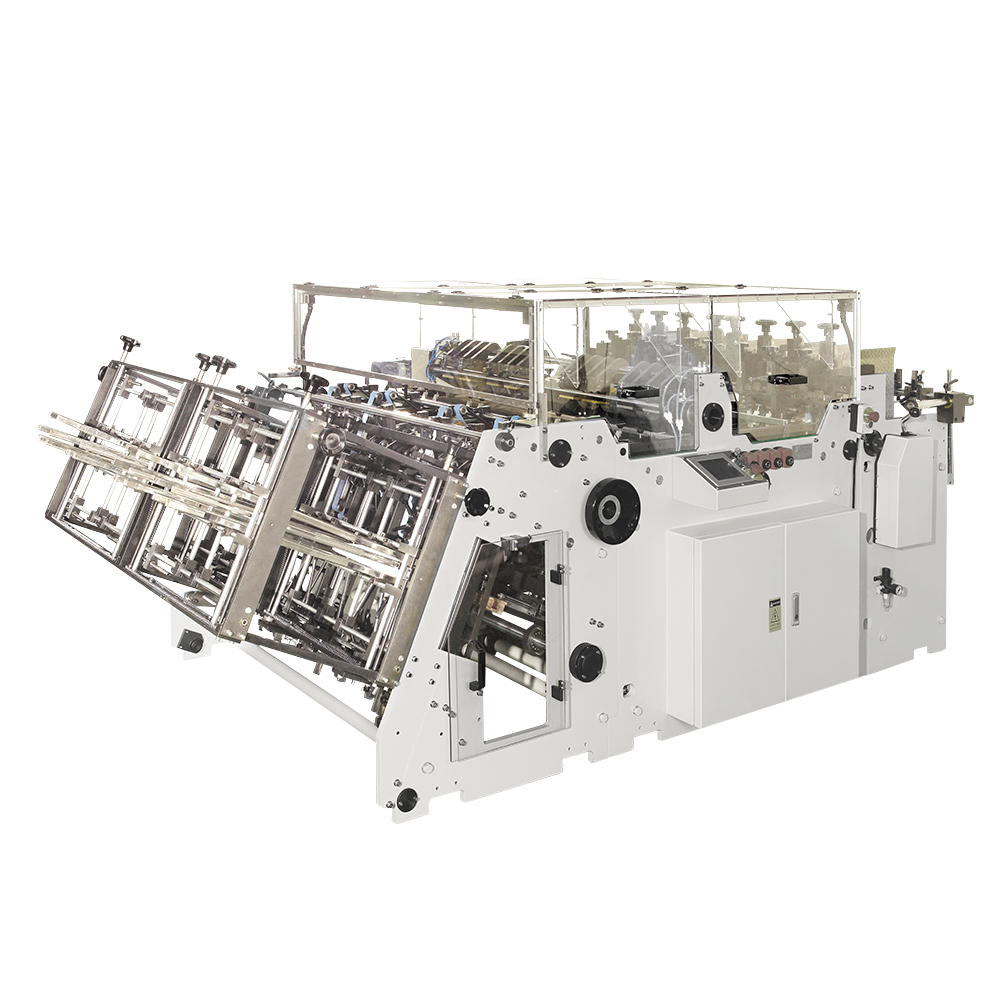

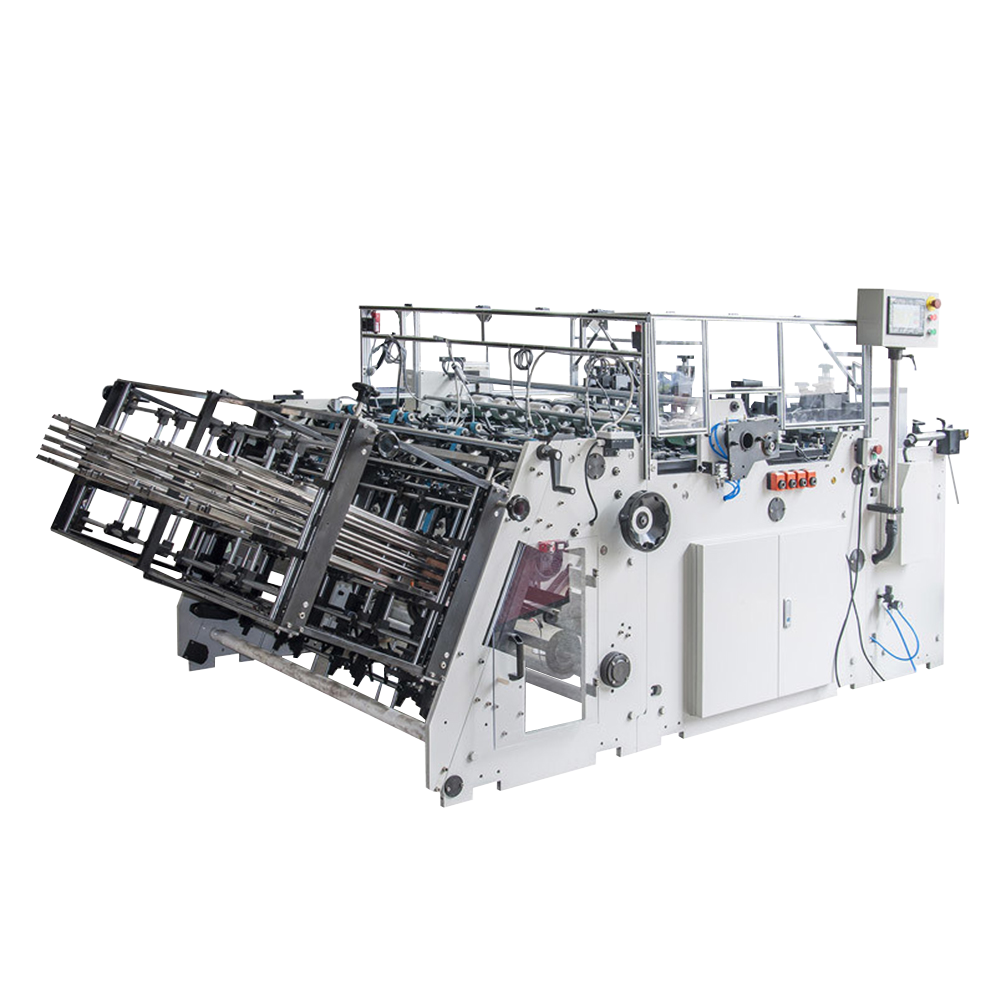

Paper Calippo Packaging Machine

Paper Calippo Cup Production Machine is a machine that produces hollow, conical, or cylindrical paper tubes (Calippo tubes) used to package products such as ice cream, frozen fruit pops, and frozen beverages. These types of packages are especially popular in the ice cream industry and offer a hygienic, single-use packaging solution.

Features of the Paper Calippo Production Machine

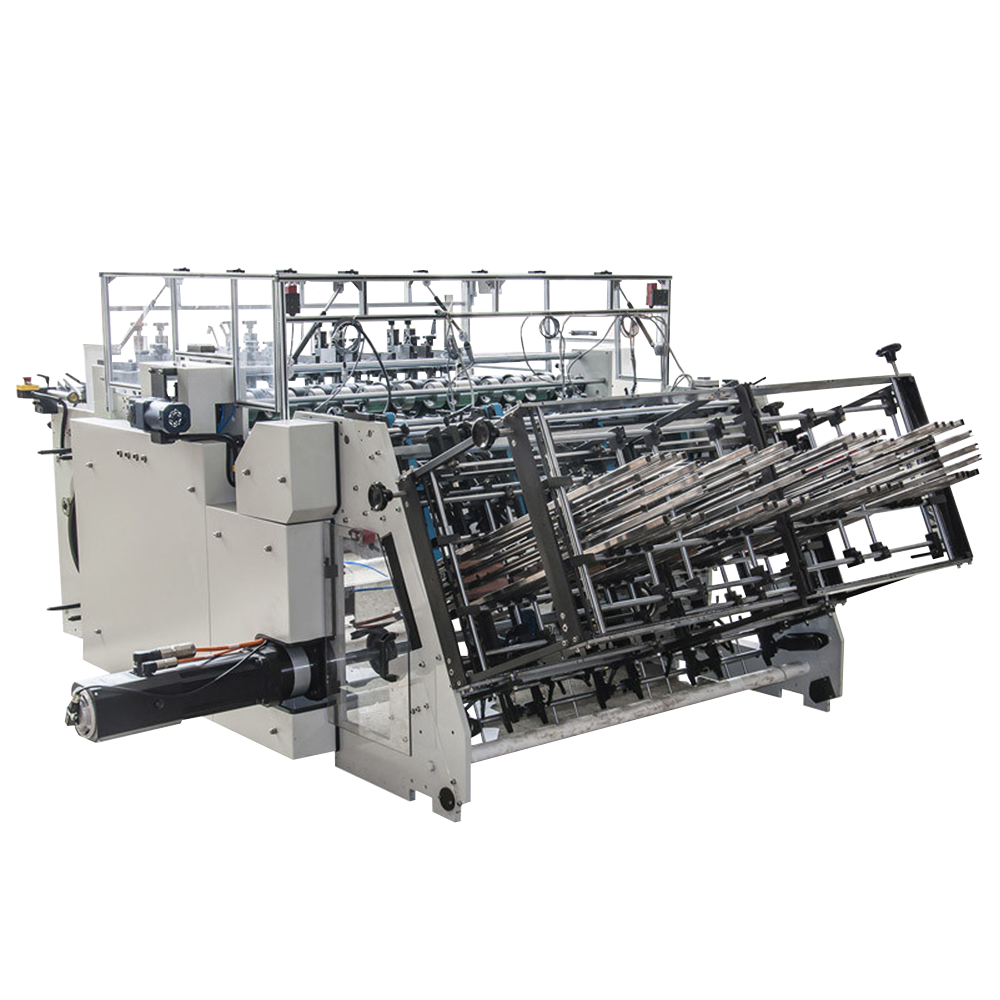

Automatic Paper Feeding and Forming: Pre-cut and trimmed and printed polyethylene, PLA, or biodegradable paper is used.

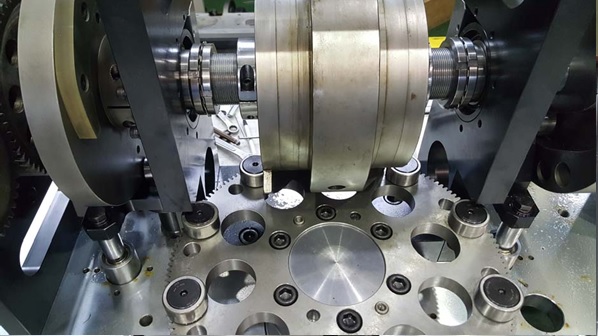

Side Sealing and Leak Prevention: Edges are ultrasonically sealed and formed to hold the product inside the tube, preventing leakage and improving durability during handling.

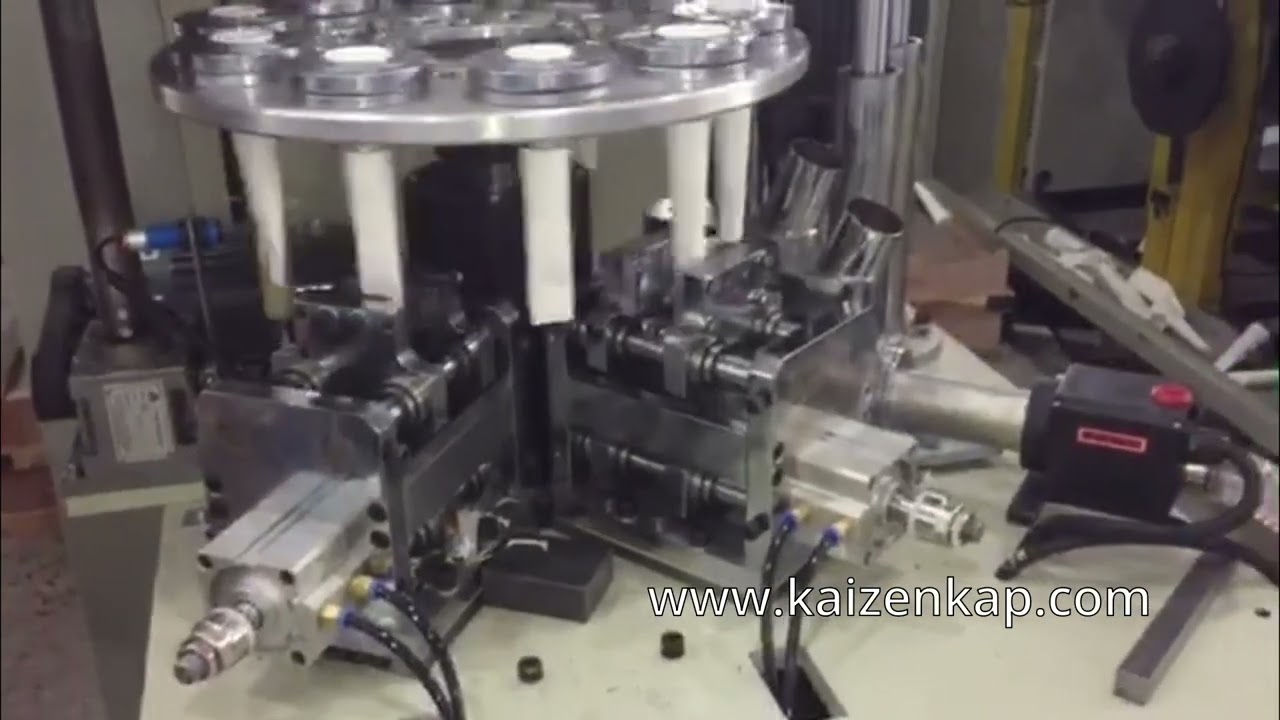

Bottom Closure: The bottom of each molded Calippo tube is sealed using a hot-air and resistive mold pressing process, preventing leaks of liquid or semi-liquid products. Once sealed, the units are stacked and prepared for packaging.

Various Size and Shape Options: By changing molds, the machine can produce Calippo tubes of different diameters and lengths, allowing production of various sizes of ice-cream or frozen drink tubes.

High Production Capacity: Designed for mass production, these machines can produce a large number of Calippo cups per minute, meeting high demand efficiently.

Eco-Friendly Material Compatibility: Offers sustainable packaging solutions by using recyclable or biodegradable paper. Paper coated on one or both sides with PE, PLA, or bio-materials is used.

Advantages

Fast and efficient production produces large quantities of Calippo tubes, saving labor costs.

Durable and leak-proof packaging ensures hygiene and safety.

Eco-friendly options enable sustainable production.

Production in various sizes and shapes offers tailored packaging solutions for different products.

| Machine Code | Production Speed | Required Paper | Power Consumption | Machine Dimensions | Machine Weight |

| KCP-50 | 40–50 pcs/min | 1 PE / 2 PE coated paper | 8 kW | L 2750 × W 2750 × H 1950 mm | 1600 kg |