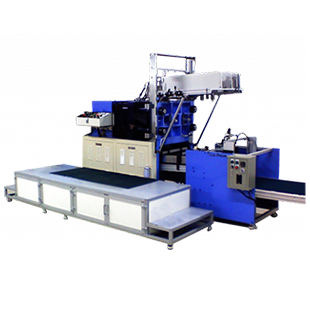

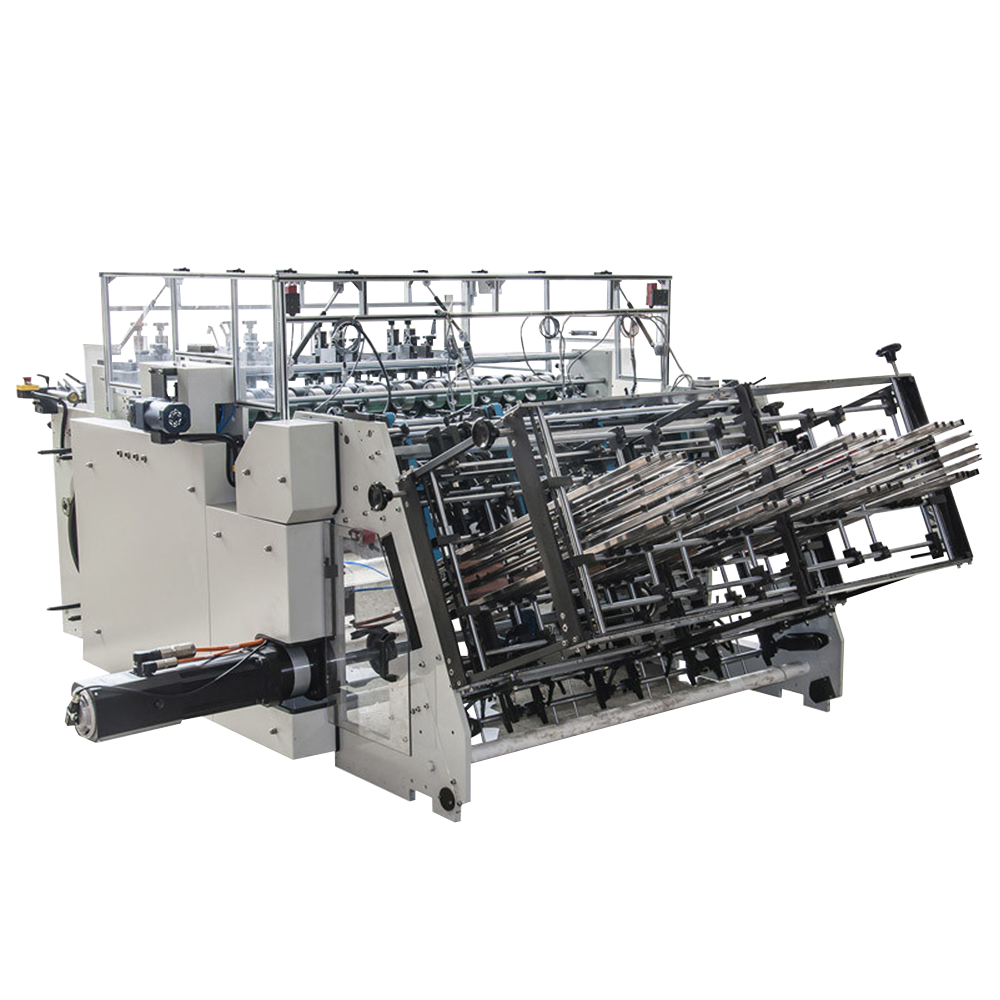

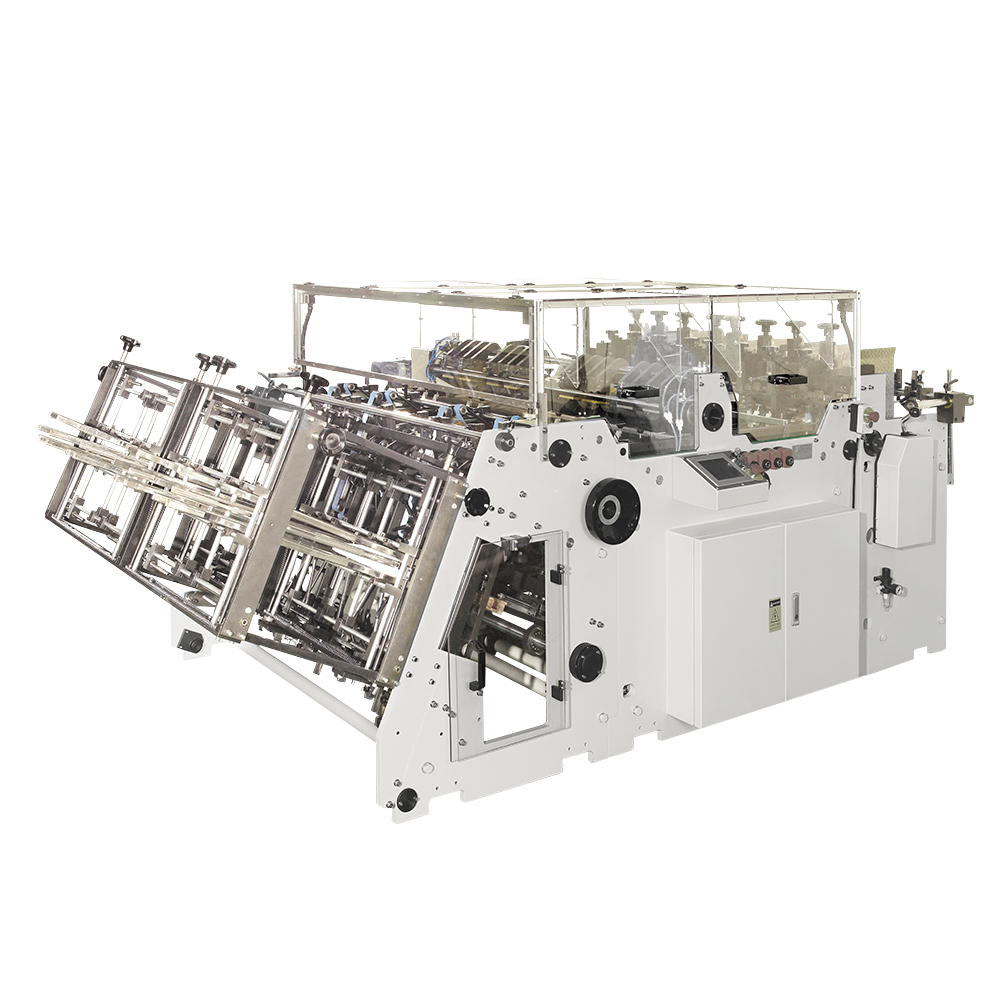

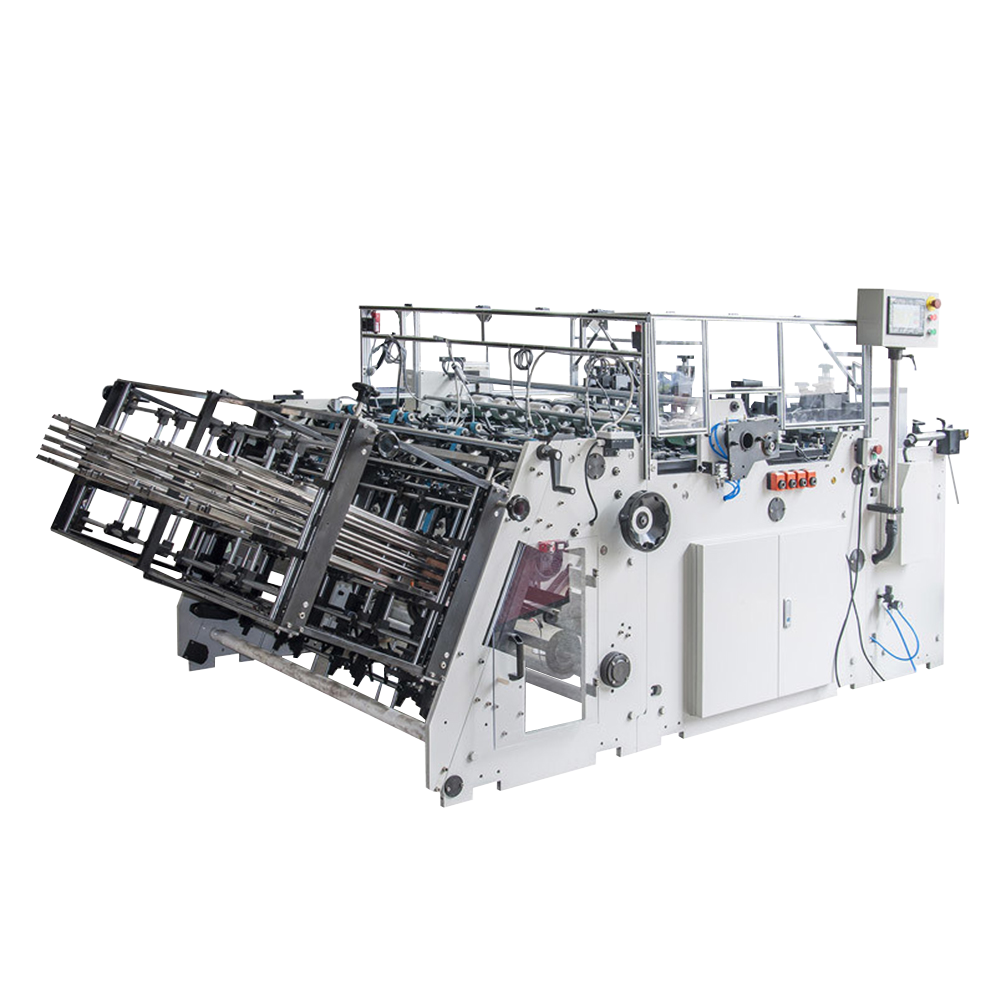

Paper Plate Production Machine

Paper Plate Production Machine refers to industrial machines that enable the automatic production of disposable paper plates. These machines are designed to produce plates made from paper or paper-coated composite materials quickly and efficiently. Paper plates, frequently used at weddings, picnics, special events, and food services, are increasingly preferred because they are eco-friendly and practical.

Features of Paper Plate Production Machines

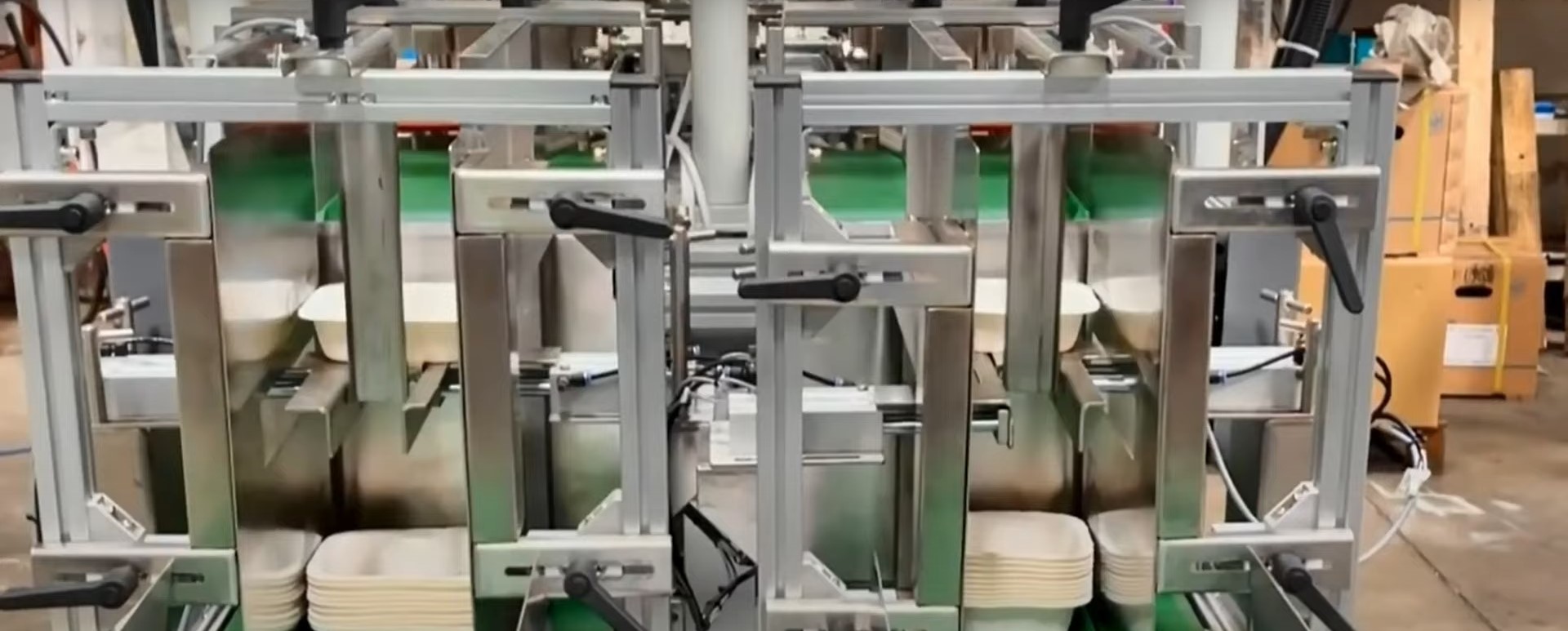

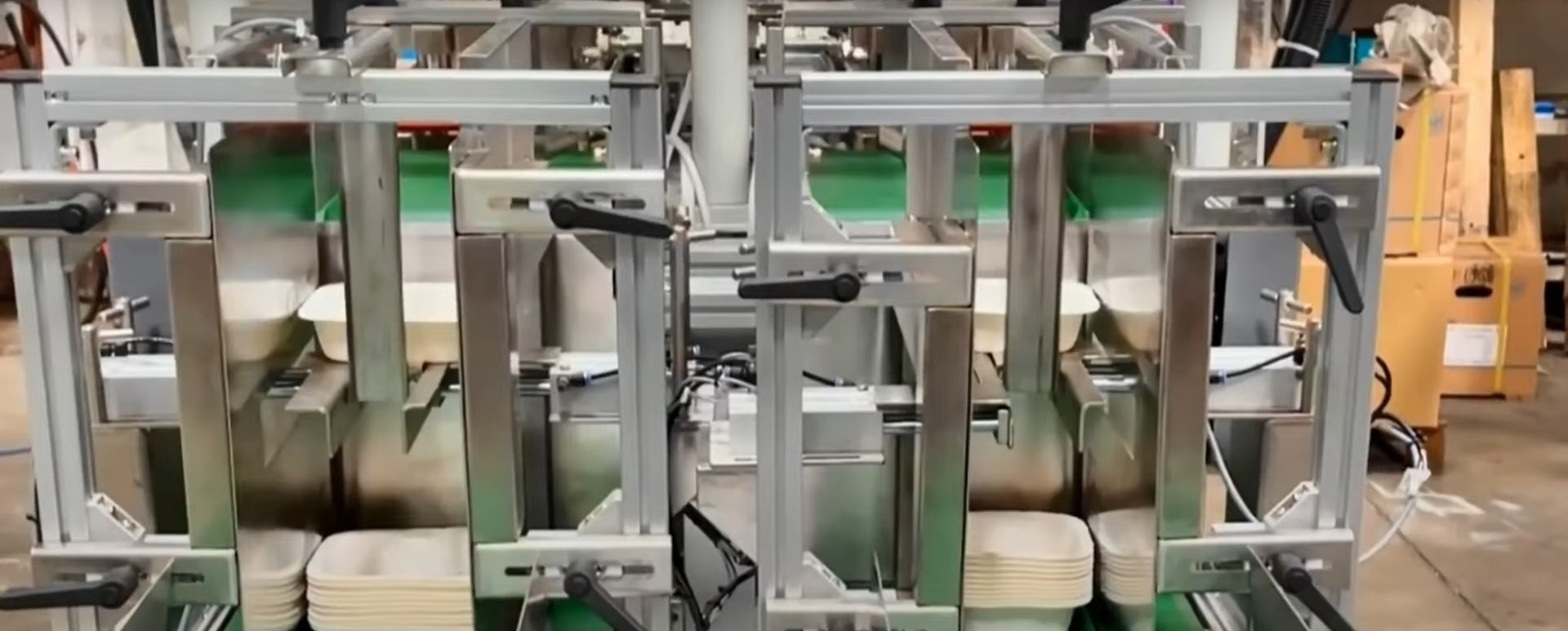

- Automatic Operation System: Pre-printed, pre-cut paper is shaped using a molding process and collected in the desired quantity.

- Molding and Pressing: The paper is pressed with heated molds to take the shape of a plate. This molding process ensures that the plates are strong and durable.

- Various Size and Shape Options: Molds can be changed to produce plates of different sizes and shapes. This feature allows for a wide product range, from small snack plates to large meal plates.

- High Production Speed: These machines have the capacity to produce hundreds of plates per minute, making them suitable for mass production and able to handle large orders quickly.

- Eco-Friendly Material Compatibility: The machine can process biodegradable paper or composite materials, thus enabling the production of eco-friendly disposable plates.

- Automatic Counting and Packaging: An integrated system counts and packages the produced plates, saving time in large-scale production.

Advantages

- Fast and efficient production: Allows large quantities of plates to be produced in a short time.

- Eco-friendly: Compatible with sustainable materials for environmentally responsible manufacturing.

- Low labor requirement and cost savings.

- Food safety compliant: Plates are produced hygienically and meet food-safety standards, ensuring durability.

These machines are an ideal solution for high-consumption businesses such as restaurants, catering services, food manufacturers, and supermarkets.

Technical Information

| PAPER PLATE & TRAY FORMING MACHINE 6500 | PAPER PLATE & TRAY FORMING MACHINE 3300 | |

|---|---|---|

| Machine Code | KZPT-01 | KZPT-02 |

| Type | Automatic dual-direction drive | Automatic dual-direction drive |

| Pressure | Max. 9 tons (adjustable) | Max. 5 tons (adjustable) |

| Feeding | Blank feeding type | Blank feeding type |

| Product Speed | MAX. 18–20 RPM 1) Ø7″: 2 cavity × 20 RPM × 2 directions = 80 pcs/min 2) Ø9″: 2 cavity × 20 RPM × 2 directions = 80 pcs/min |

MAX. 18–20 RPM 1) Ø7″: 2 cavity × 20 RPM × 2 directions = 40 pcs/min 2) Ø9″: 1 cavity × 20 RPM × 2 directions = 20 pcs/min |

| Production Capacity | MAX. 65,000 pcs / 8 hours | MAX. 20,000 pcs / 8 hours |

| Power Requirement | 3Ø, 380/430V, 50/60Hz | 3Ø, 380/430V, 50/60Hz |

| Power Consumption | Approx. 25 kW/hour | Approx. 10 kW/hour |

| Air Pressure | Approx. 0.8 m²/min, 5 kg/cm² | Approx. 0.8 m²/min, 5 kg/cm² |

| Heater | 1.5 kW × 16 pcs | 1.8 kW × 4 pcs |

| Vacuum Pump | 1 HP | 0.5 HP |

| Mould Capacity | MAX. 6 sets applicable | MAX. 2 sets applicable |

| Material | PULP (200–2,000 GSM) / VALLEY BOARD | PULP (200–2,000 GSM) / VALLEY BOARD |

| Stroke | 140 mm | 140 mm |

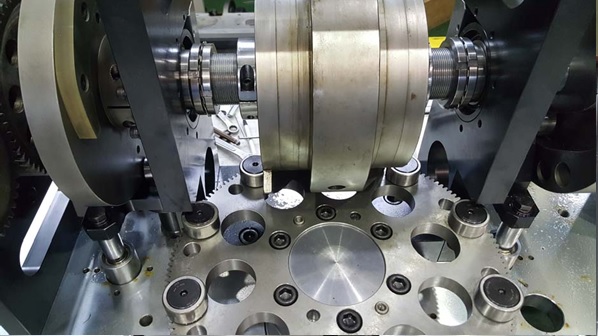

| Lubrication | Automatic lubrication device | Automatic lubrication device |

| Control | PLC with touch screen | PLC with touch screen |

| Machine Dimensions | 6,000 mm (L) × 1,800 mm (W) × 1,900 mm (H) | 3,000 mm (L) × 1,800 mm (W) × 1,900 mm (H) |

| Machine Weight | 2,300 kg | 1,500 kg |

Other Products