Flexo Printing And Die Cutting Machine From Coil

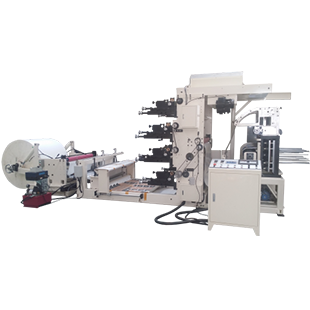

Flexo Printing and Die Cutting Machine refers to two key technologies widely used in the packaging paper printing industry. By combining these processes, high-efficiency printing and cutting operations are performed. Our machine is South Korea-made, robust, simple to use, and designed for long-term operation.

Flexo printing is a fast and efficient printing technology used for flexible materials. It is commonly applied in packaging, paper, and labeling applications.

Working Principle of Flexo Printing and Die Cutting Machine

Flexo Plates: Flexo printing uses flexible printing cliché plates made from photopolymer material. These plates are mounted on a cylinder to transfer ink onto the printing surface.

Ink Application: Ink is transferred to the printing cliché via a special cylinder called an anilox roller. The microscopic cells of this roller control the precise amount of ink applied.

Printing: The printing plate contacts the substrate (paper, plastic, metal foil, etc.) to transfer the ink.

Cutting Machine: After printing, the material is cut into specific shapes and sizes. Our machine is designed for cutting flexible materials (paper, cardboard, plastic, etc.) into desired shapes or dimensions.

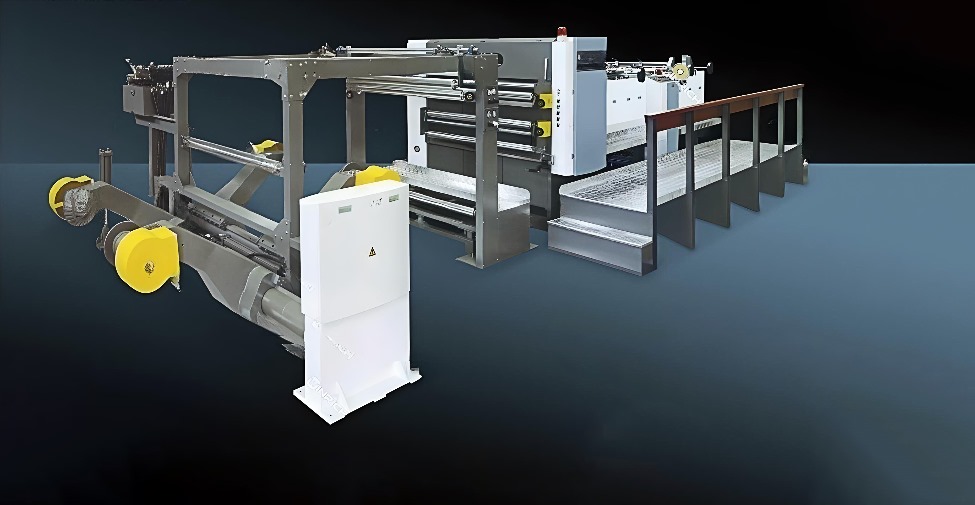

Unwinding from Rolls: Material is fed into the cutting machine in rolls. Our machine automatically feeds the material continuously while performing cutting operations.

Die Cutting: Wooden die cutting blades are used for cutting. The die is a metal or steel form shaped to the cutting pattern. The material is pressed against this die to form the shape.

High Speed: The cutting process is fast and ideal for large volume production.

High Precision: Dies allow highly accurate cutting, which is especially important for labels and packaging products.

Flexibility: Cutting can be done on different material types such as paper, plastic, foil, etc.

Low Labor Costs: Automatic feeding and cutting systems reduce labor costs significantly.

Advantages of Flexo Printing and Die Cutting Machine

Fast Printing: Flexo printing operates at high speeds, enabling mass production.

Printing on Various Materials: Capable of printing on paper, plastic, and many other flexible materials.

High Quality: Produces high-resolution prints with detailed graphics, texts, and colors.

Cost Efficiency: Enables low-cost production for large print runs.

Applications of Flexo Printing and Die Cutting Machine

Packaging industry (especially flexible packaging) – Labels – Cardboard boxes – High volume printing jobs – Paper cups

| Machine Code | Production speed | Material | Color | Cutting Width | Ink | Electricity Consumption | Machine Dimensions | Machine Weight |

| KRD-150 | 150 beats/minute | 1 pe 2 pe paper | 3-4 Color | 500×400 mm | Water Based Ink | 15-25 kw | 9500(U)X2000(G)X2200(Y) | 5.500 kg |