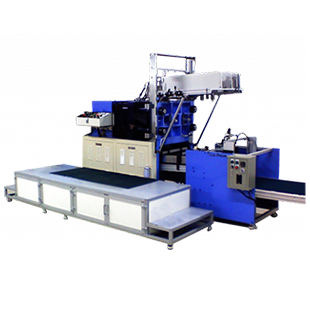

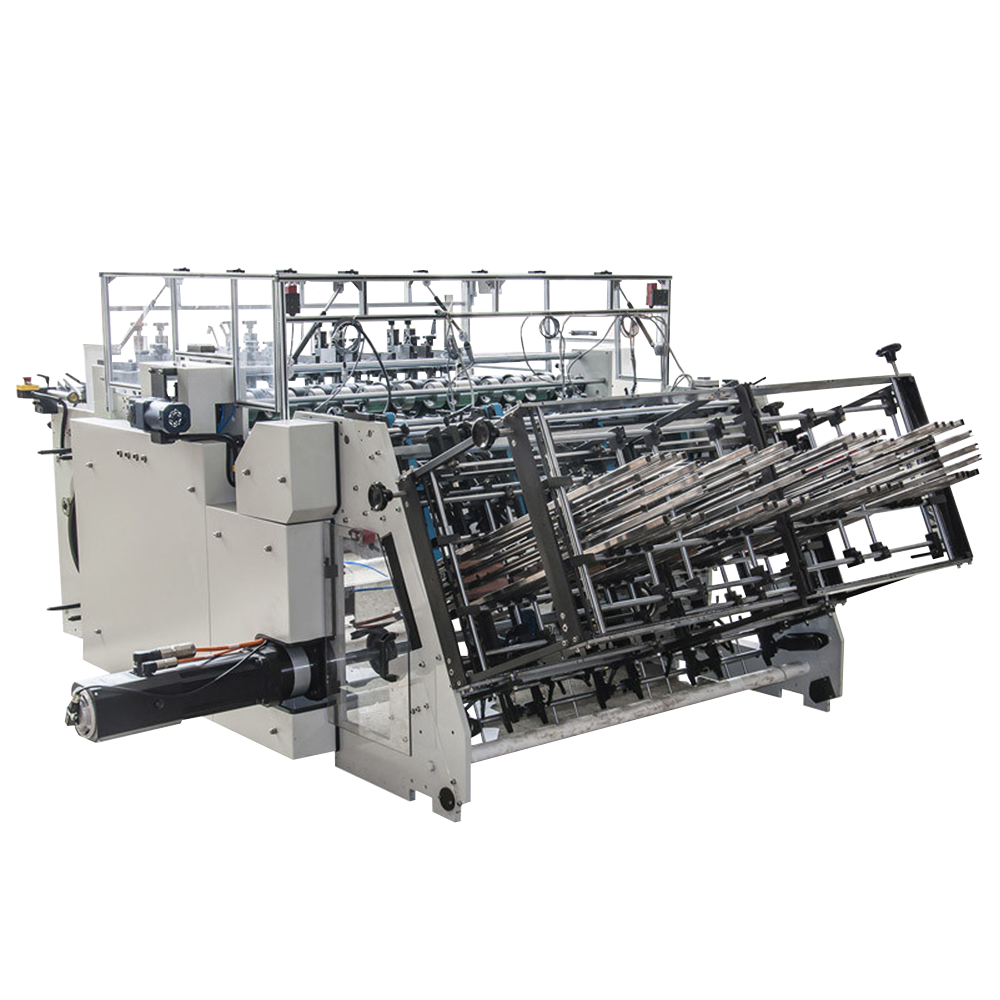

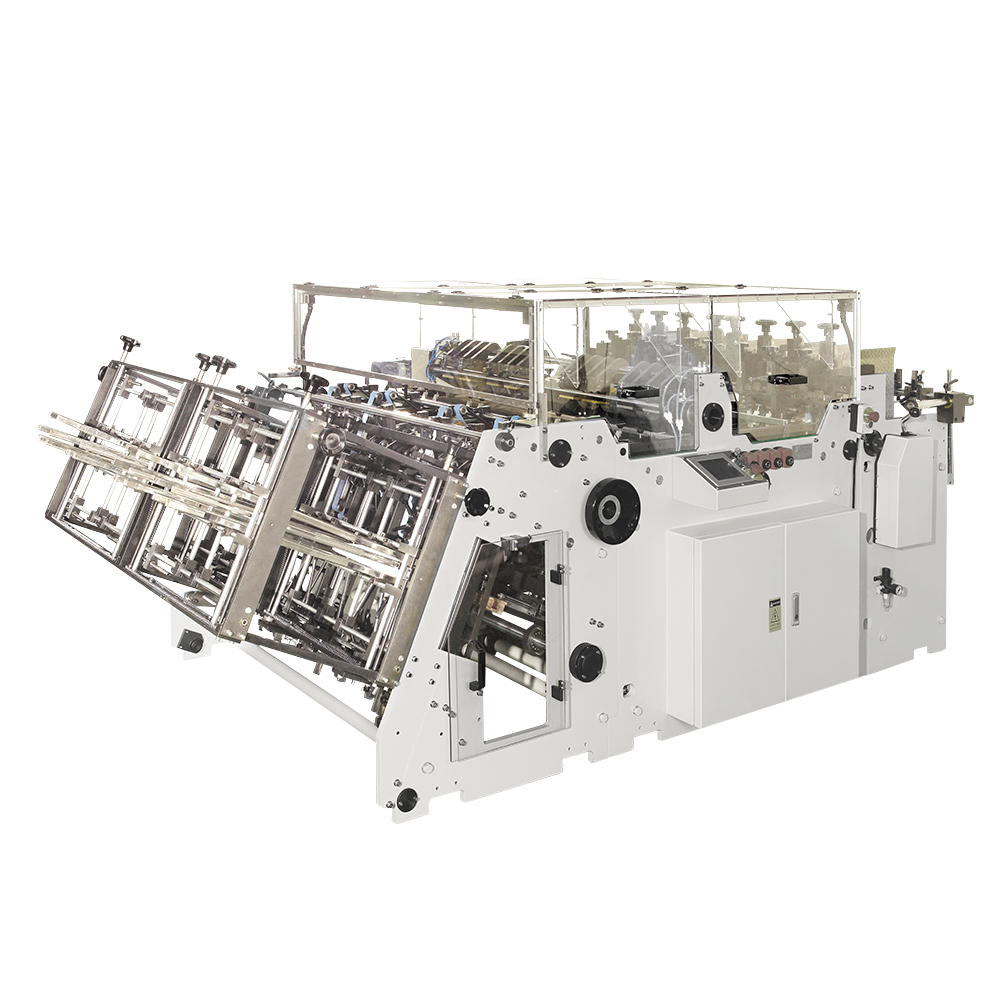

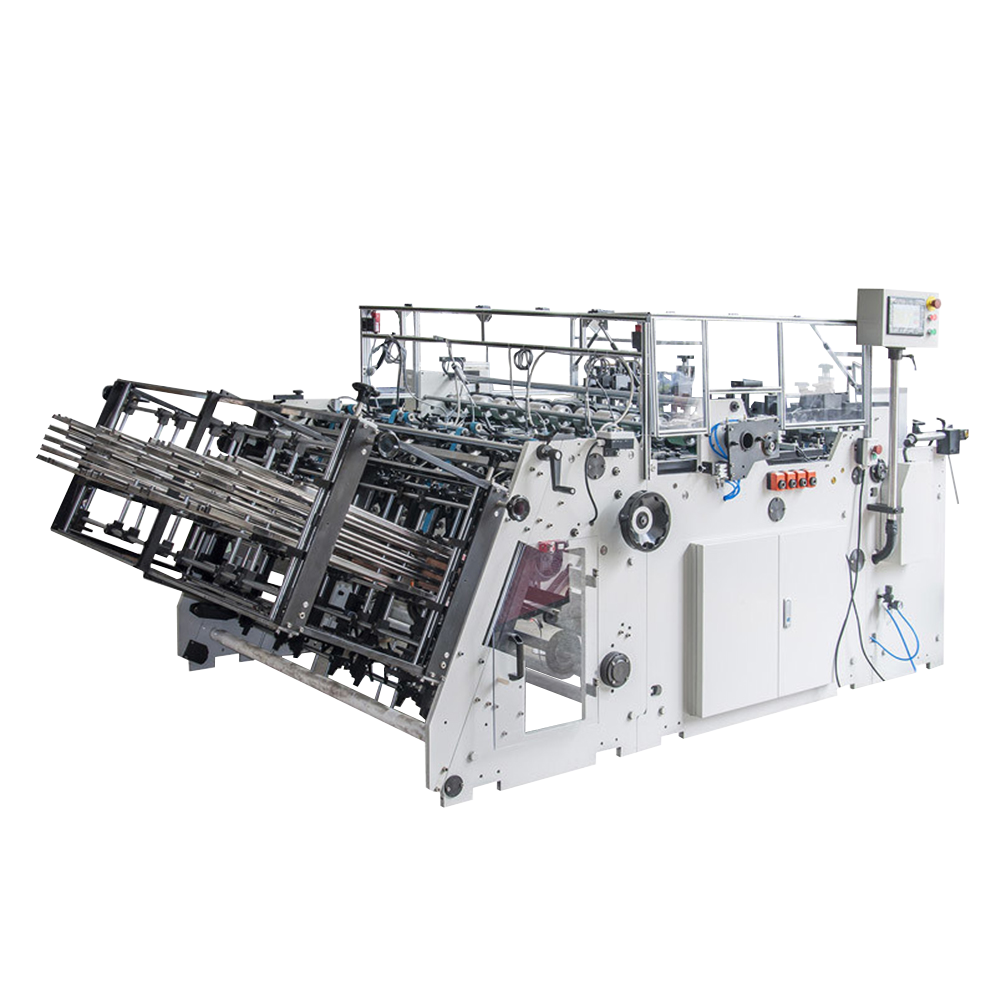

Paper Food Box Production Machine

Paper Food Box Production Machine refers to industrial machines that enable the automatic production of disposable paper plates. These machines are designed to produce plates made of paper or paper-coated composite materials quickly and efficiently. Paper plates, commonly used at weddings, picnics, special events, and food services, are increasingly preferred for being eco-friendly and practical.

Features of Paper Plate Production Machines

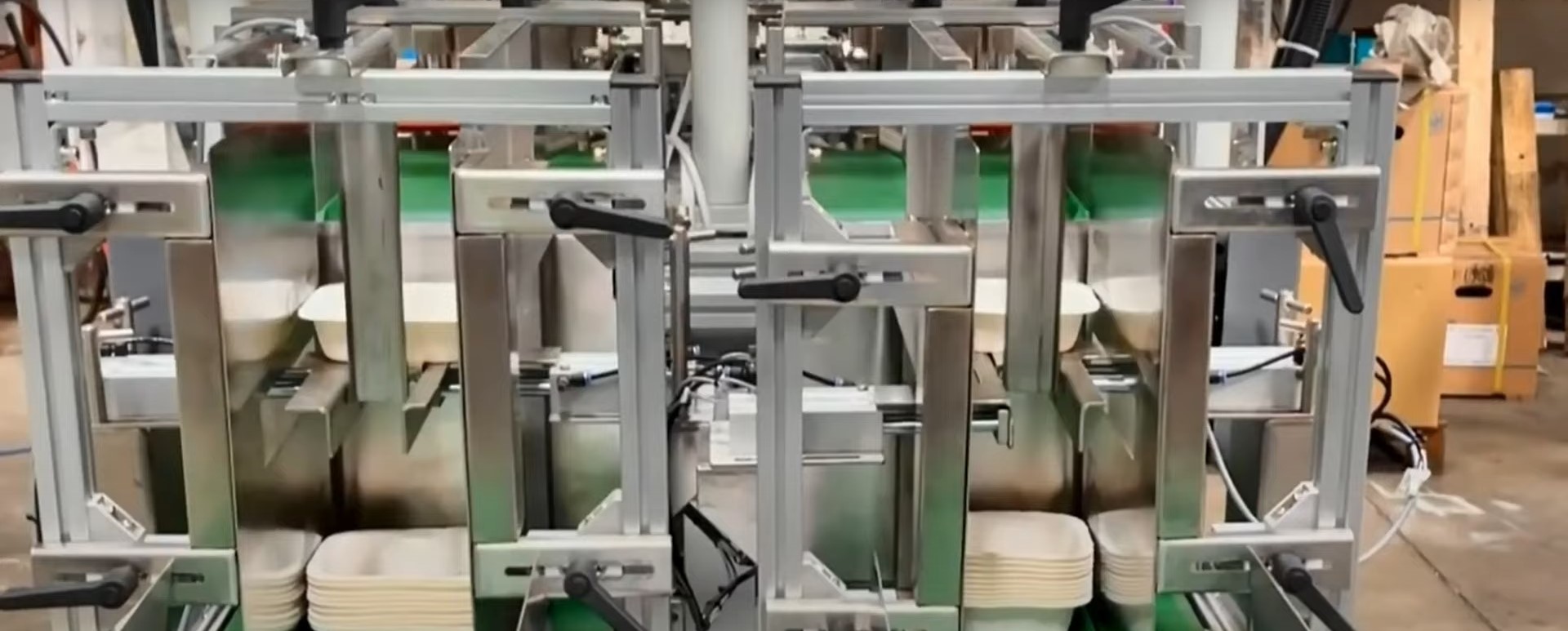

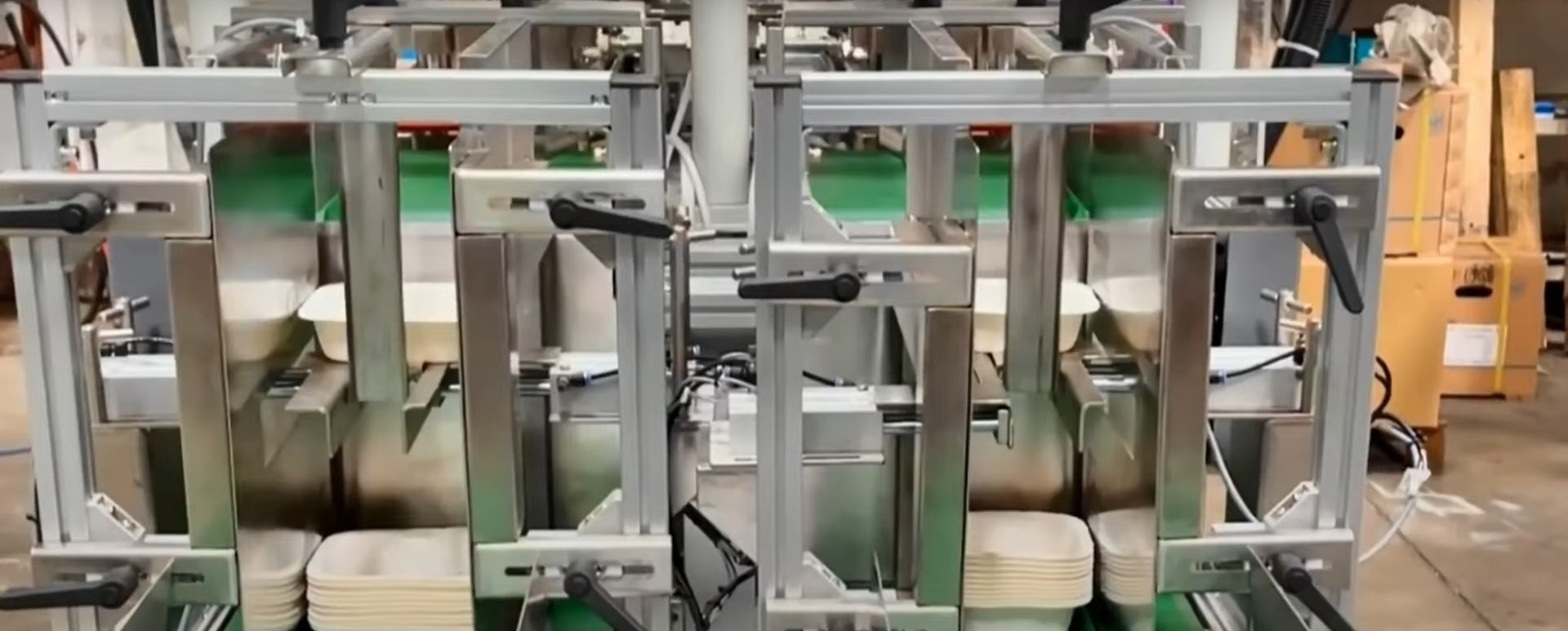

- Automatic Operation System: Pre-printed and pre-cut paper is shaped through molding and collected in desired quantities.

- Molding and Pressing: Paper is pressed with heated molds to form the plate shape, ensuring strength and durability.

- Various Sizes and Shapes: Interchangeable molds allow for the production of plates in different sizes and shapes—from small snack plates to large meal plates.

- High Production Speed: Capable of producing hundreds of plates per minute, making it ideal for mass production.

- Eco-Friendly Material Compatibility: Compatible with biodegradable paper or composite materials for sustainable output.

- Automatic Counting and Packaging: Plates are automatically counted and packed, saving time in large-scale production.

Advantages

- Fast and efficient production process for large quantities.

- Eco-friendly and supports sustainable manufacturing.

- Low labor requirement and cost savings.

- Compliant with food safety standards, ensuring hygiene and durability.

These machines are ideal for high-demand environments such as restaurants, catering services, food producers, and supermarkets.

Technical Information

| Specification | Paper Plate & Tray Forming Machine 6500 | Paper Plate & Tray Forming Machine 3300 |

|---|---|---|

| Machine Code | KZPT-01 | KZPT-02 |

| Type | Automatic bi-directional drive | Automatic bi-directional drive |

| Pressure | Max. 9 tons (adjustable) | Max. 5 tons (adjustable) |

| Feeding | Blank feed type | Blank feed type |

| Product Speed | MAX. 18–20 RPM 1) Ø7″: 2 cavities × 20 RPM × 2 sides = 80 pcs/min 2) Ø9″: 2 cavities × 20 RPM × 2 sides = 80 pcs/min |

MAX. 18–20 RPM 1) Ø7″: 2 cavities × 20 RPM × 2 sides = 40 pcs/min 2) Ø9″: 1 cavity × 20 RPM × 2 sides = 20 pcs/min |

| Production Capacity | MAX. 65,000 pcs / 8 hours | MAX. 20,000 pcs / 8 hours |

| Power Requirement | 3Ø, 380/430V, 50/60Hz | 3Ø, 380/430V, 50/60Hz |

| Power Consumption | Approx. 25 kW/h | Approx. 10 kW/h |

| Air Pressure | Approx. 0.8 m³/min, 5 kg/cm² | Approx. 0.8 m³/min, 5 kg/cm² |

| Heater | 1.5 kW × 16 units | 1.8 kW × 4 units |

| Vacuum Pump | 1 HP | 0.5 HP |

| Mold Capacity | Max. 6 sets applicable | Max. 2 sets applicable |

| Material | PULP (200–2000 GSM) / Valley Board | PULP (200–2000 GSM) / Valley Board |

| Working Stroke | 140 mm | 140 mm |

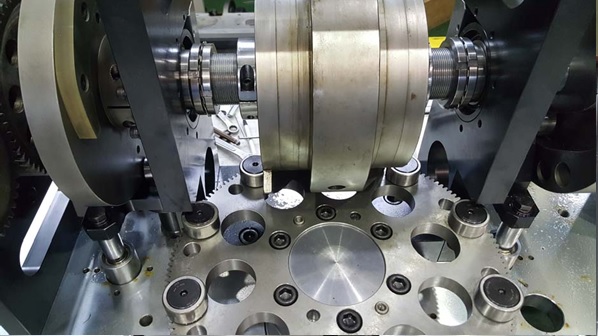

| Lubrication | Automatic lubrication system | Automatic lubrication system |

| Control | PLC with touch screen | PLC with touch screen |

| Machine Dimensions | 6000 mm (L) × 1800 mm (W) × 1900 mm (H) | 3000 mm (L) × 1800 mm (W) × 1900 mm (H) |

| Machine Weight | 2,300 kg | 1,500 kg |

Other Products