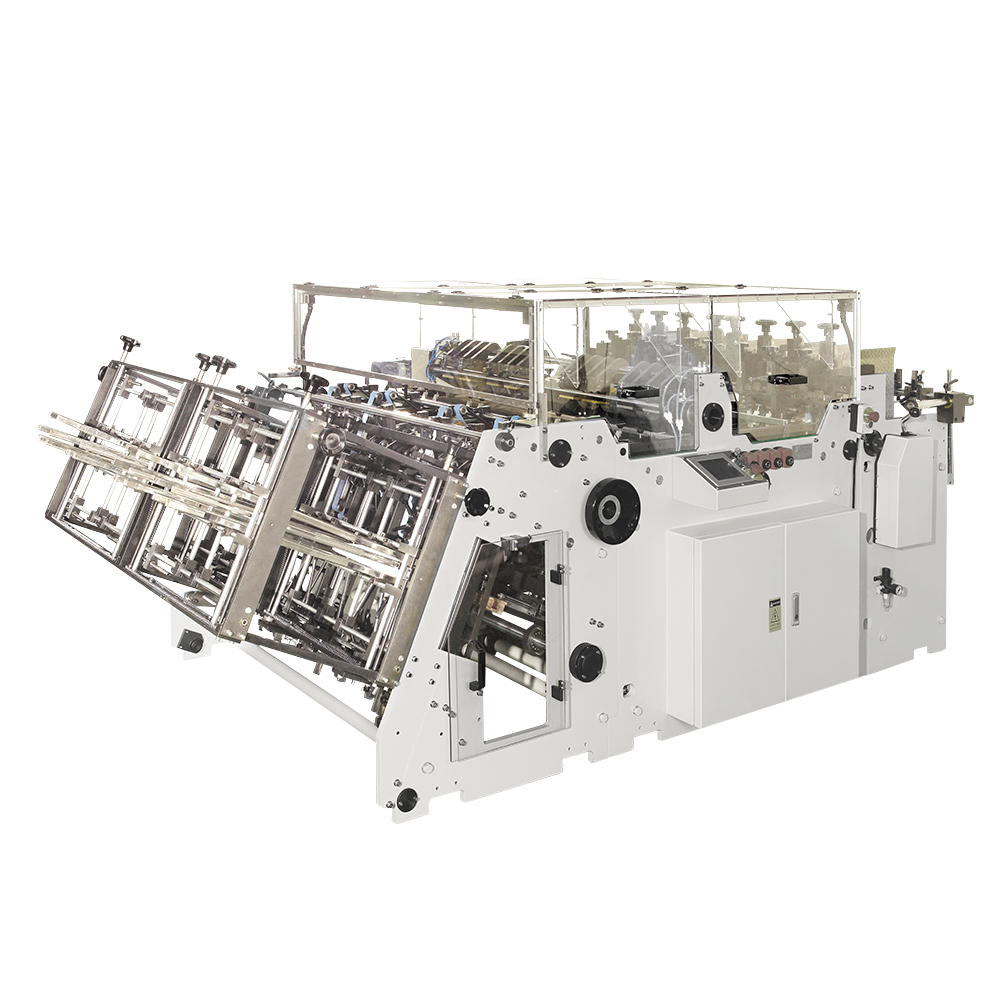

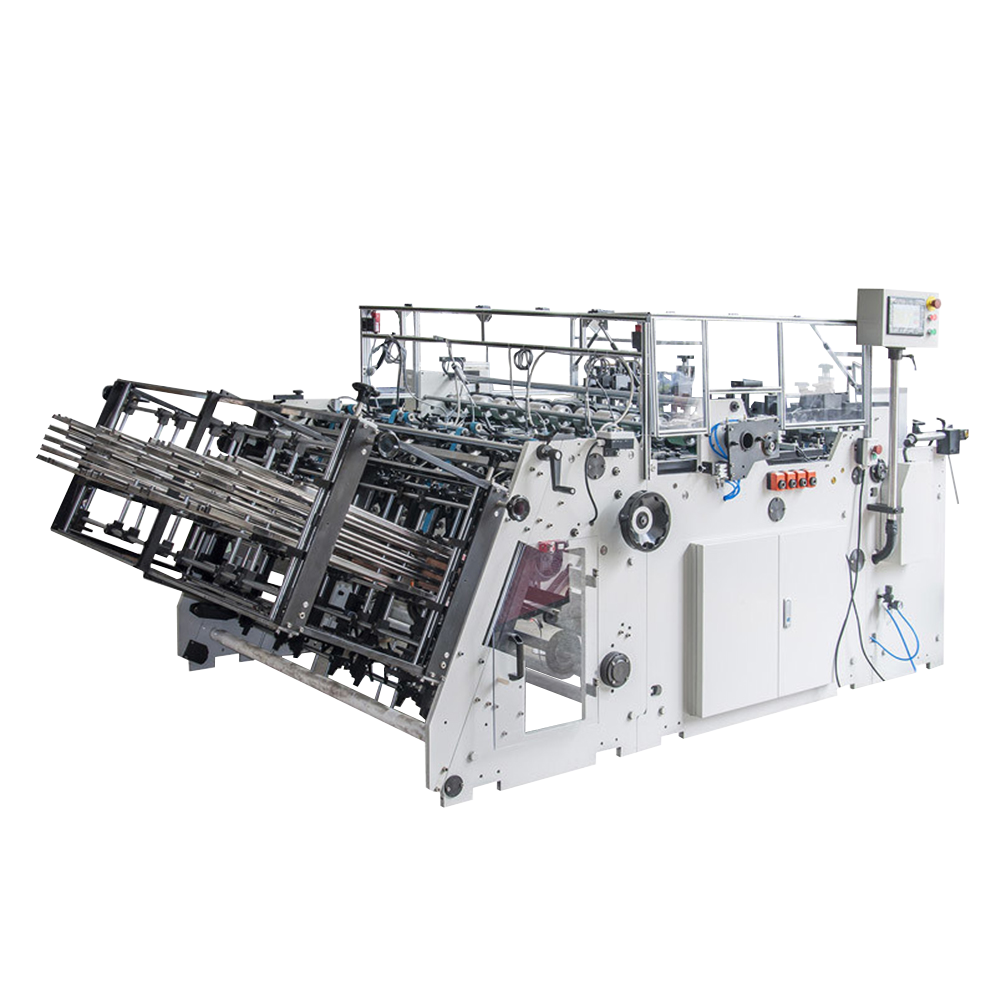

Square Bottom Paper Bag Production Machine

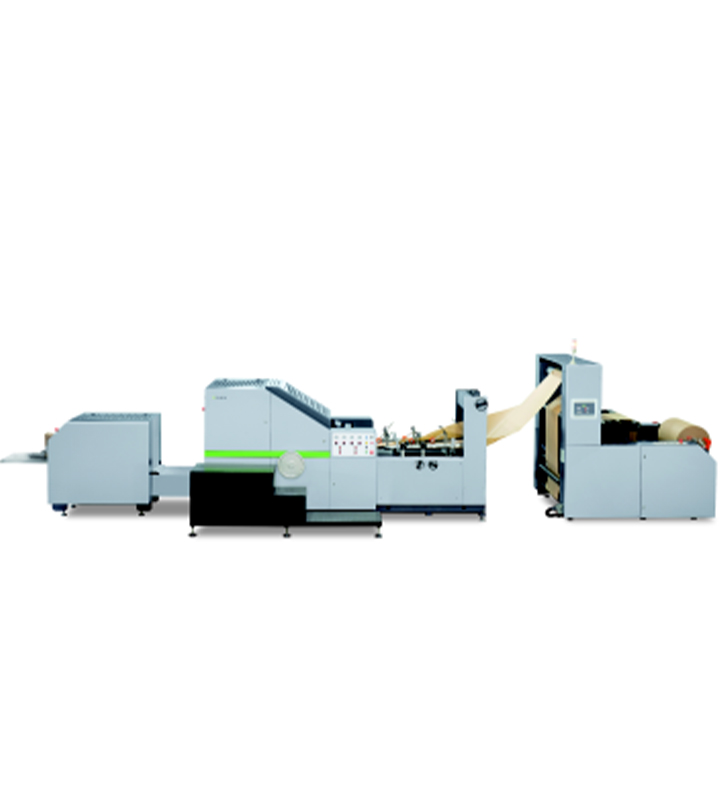

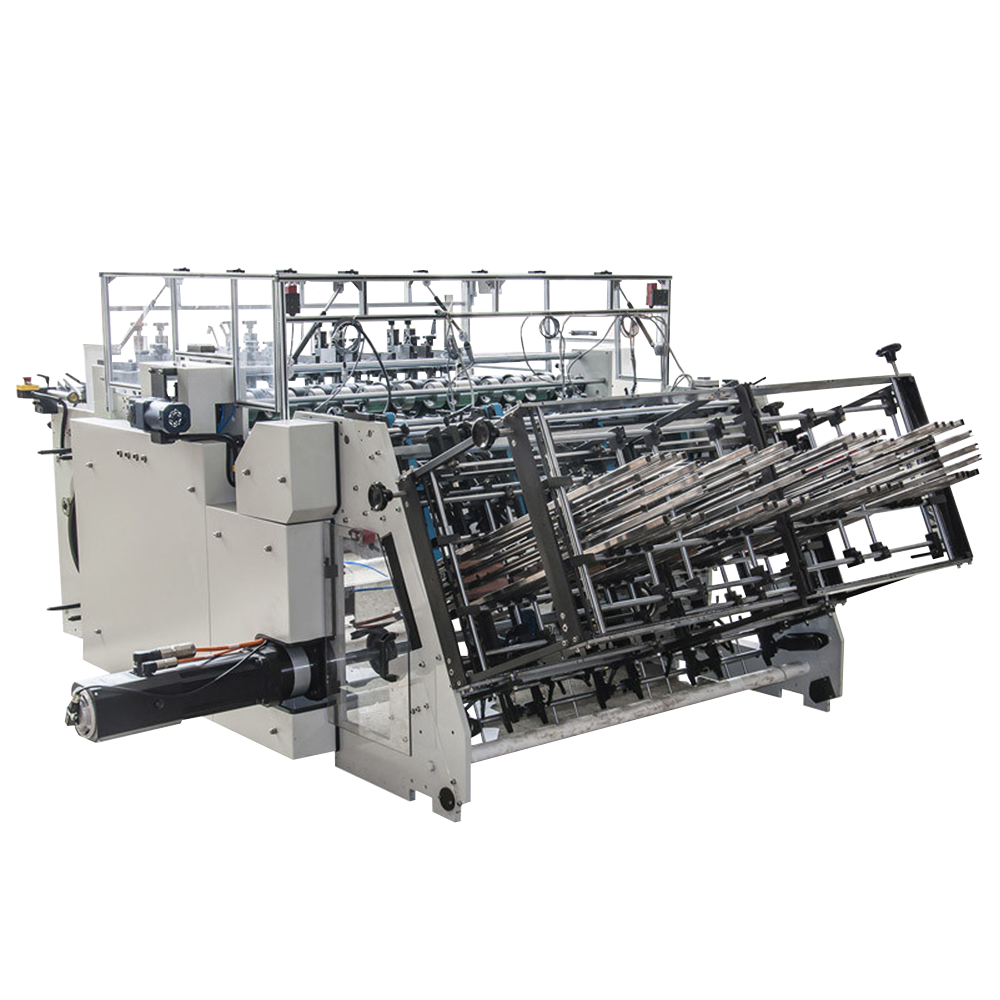

Square Bottom Paper Bag Making Machine is used to automatically produce rectangular or square bottom paper bags from white and brown kraft paper or food-grade papers. The feeding system is roll paper. It integrates automatic center gluing, printing tracking, folding, fixed-length cutting, bottom indenting, bottom folding, bottom gluing, bag bottom forming, and one-time bag collection.

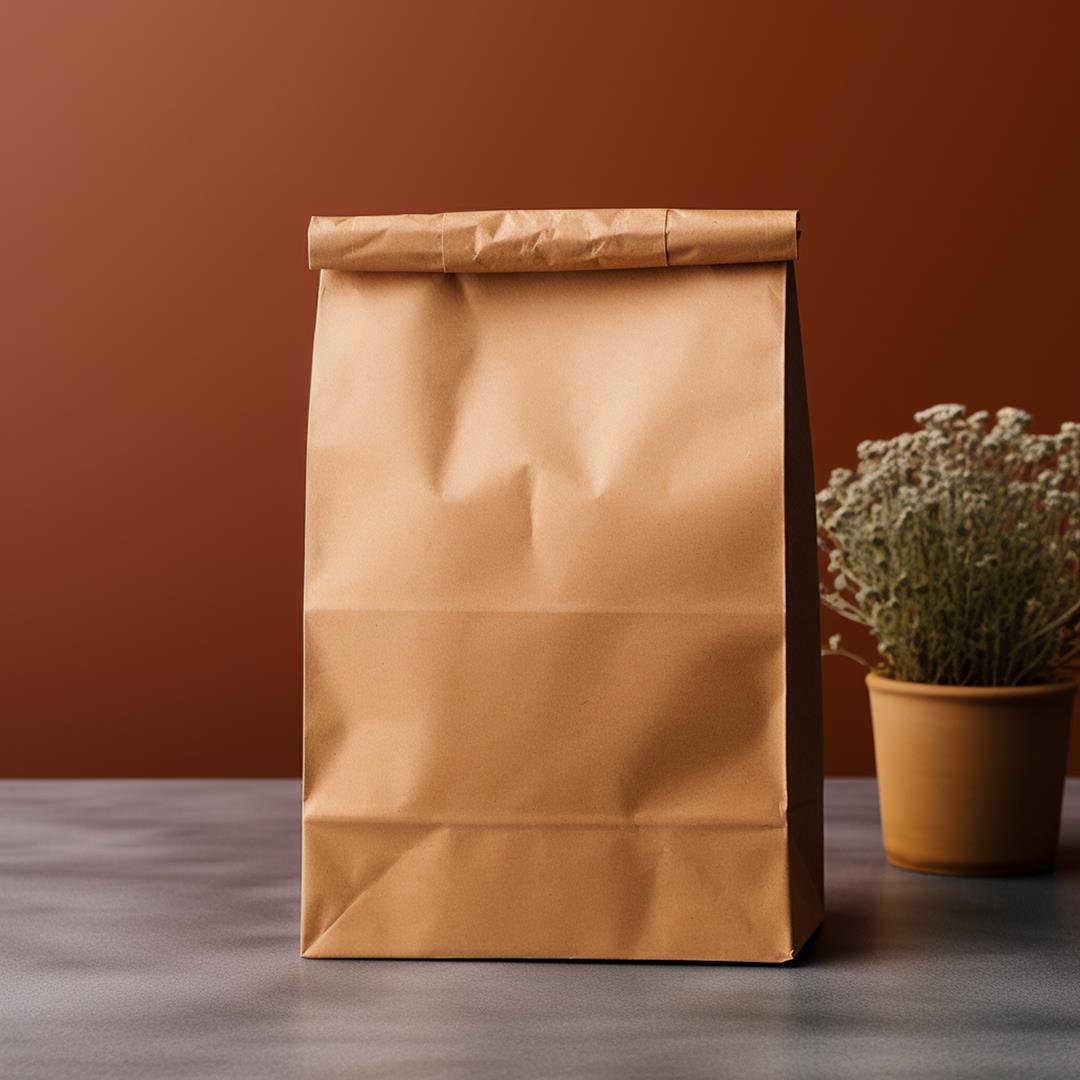

This machine uses a servo motor for motion control. It ensures easy operation, efficient production, and smooth and stable performance. Square bottom paper bags can be produced in various features and sizes for bread bags, snack food bags, shopping bags, and other environmentally friendly special paper bag machines. The square bottom paper bag machine is specialized equipment used in the production of square or flat-bottom paper bags. These bags are commonly used for packaging various products including groceries, snacks, and produce.

Square Bottom Paper Bag Making Machine is our industrial machine used especially for producing durable, wide-based, and neatly standing paper bags. Square bottom paper bags are suitable for use in shopping bags, food packaging, bag manufacturing, and similar applications. This machine ensures the paper bag bottoms are formed smoothly and sturdily.

Features of Square Bottom Paper Bag Making Machine

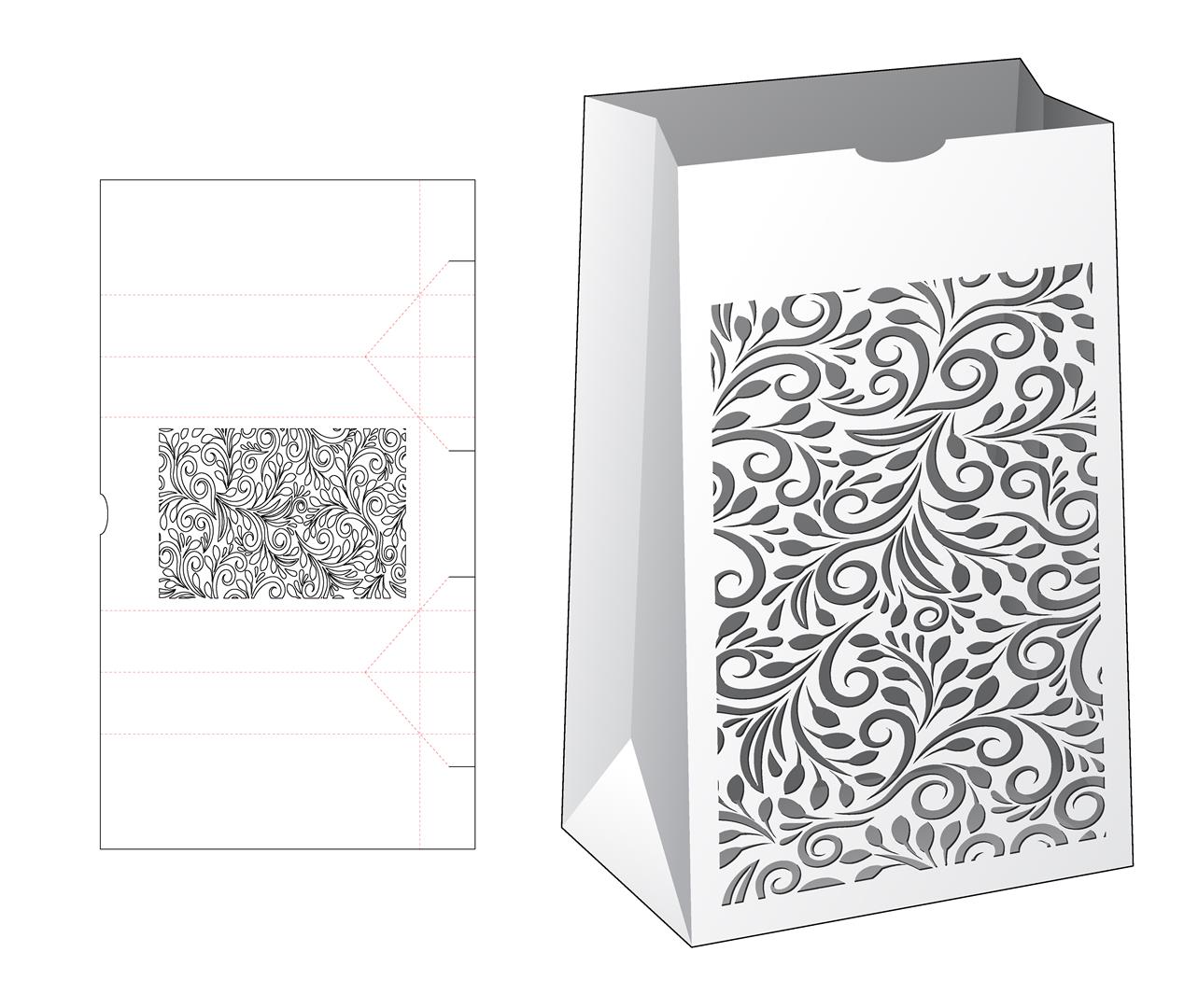

Square Bottom Design: Square bottom paper bags provide a flat and wide area at the base, allowing the bag to stand upright and the contents to be carried more stably. This significantly enhances the stability of larger bags. The machine shapes and folds the base of the paper into a square or rectangular form.

High-Speed Production: This machine can produce a large number of bags per minute. Fast production is a great advantage during high-demand periods. The machine performs each step quickly and efficiently with automated systems.

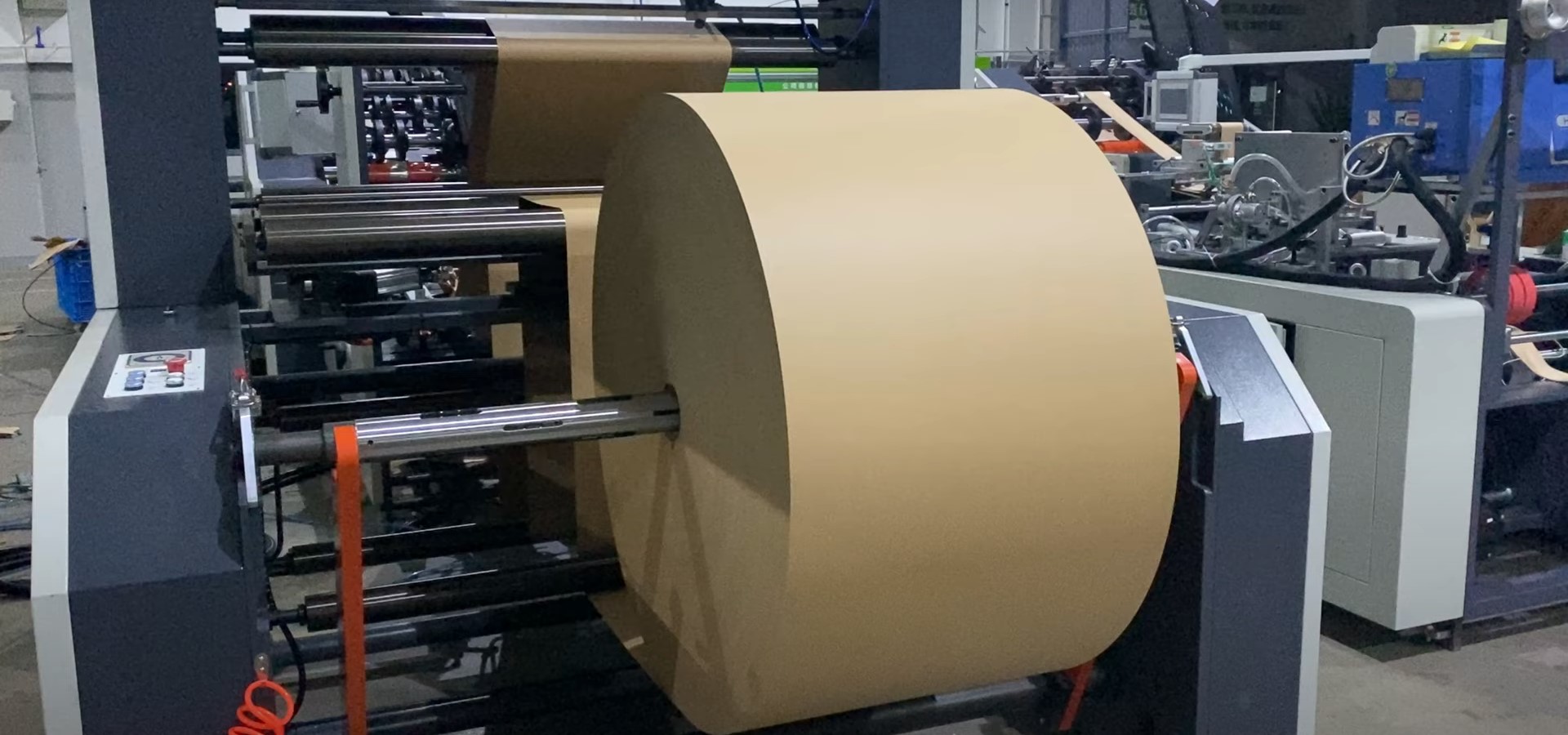

Various Paper Options: Durable, recyclable materials such as kraft paper are used. However, papers of different weights and types can also be used. The thickness of the paper directly affects the strength and durability of the bag.

Various Sizes: This machine can be adjusted to produce square bottom bags in different sizes. Users can customize the sizes based on industrial needs and consumer demands.

Automatic Process: The cutting, folding, gluing, assembling, and bottom shaping of the paper are all done automatically. A printing unit can also be added to the machine to enable custom printing on the paper bags.

Working Principle of Square Bottom Paper Bag Making Machine

Feeding the Paper Roll: The paper is fed into the machine in roll form. This serves as the primary material for cutting and other processes.

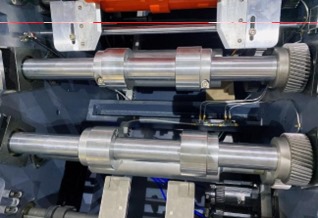

Cutting and Folding the Paper: The machine cuts the paper roll into desired lengths. At the same time, the paper is folded to form the base and sides of the bag.

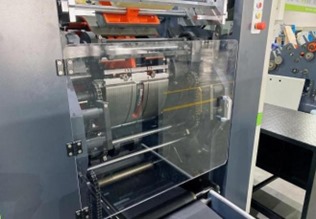

Forming the Bottom (Square Base): After folding, the bottom of the bag is shaped into a square. Gluing is applied to the bottom area by the machine.

Advantages of Square Bottom Paper Bag Making Machine

Durable and Practical Bags: Square bottom paper bags have high carrying capacity, are durable, and can stand upright properly. This is especially important for shopping and food industries.

Fast Production: Fully automatic machines provide high-speed production, enabling fast response to high production demands.

Eco-Friendly Production: Paper bags are made from recyclable and biodegradable materials, making them environmentally friendly.

Flexible Design Options: Bags can be produced in various sizes and designs. Additionally, a printing unit can be added, making them ideal for promotional use.

Low Cost: Fully automatic systems reduce labor requirements, lowering production costs and increasing efficiency.

Applications of Square Bottom Paper Bags

Shopping Bags: Commonly used in retail stores and shopping centers.

Food Packaging: Especially used in the food industry for packaging bread, pastries, flour, and similar products.

Textile and Fashion: Preferred for packaging products such as clothing and shoes.

Promotional Use: Brands can add logo prints and custom designs to use square bottom paper bags as promotional items.

| Model | KAI-190S | KAI-330S | KAI-450S | KAI-450BS | KAI-550S |

| Cut length | 190-370mm | 260-530mm | 260-530mm | 360-800mm | 360-800mm |

| Paper bag width | 80-190mm | 130-330mm | 150-450mm | 220-450mm | 220-550mm |

| Paper bag base width | 50-100mm | 70-180mm | 70-180mm | 100-250mm | 100-250mm |

| Paper thickness | 45-120g/m2 | 60-160g/m2 | 60-160g/m2 | 80-160g/m2 | 80-160g/m2 |

| Paper roll width | 290-610mm | 430-1050mm | 570-1290mm | 670-1430mm | 670-1630mm |

| Maximum paper roll diameter | 1200mm | 1200mm | 1200mm | 1200mm | 1200mm |

| Paper roll inner diameter | 76mm | 76mm | 76mm | 76mm | 76mm |

| Power | 11kw | 8kw | 8kw | 15kw | 15kw |

| Machine speed | 30-200pcs/min | 60-200pcs/min | 60-180pcs/min | 30-120pcs/min | 30-100pcs/min |

| Air supply | >0.12m3/min 0.6MPa | >0.12m3/min 0.6MPa | >0.12m3/min 0.6MPa | >0.12m3/min 0.6MPa | >0.12m3/min 0.6MPa |

| Machine weight | 5ton | 8.5ton | 10ton | 12ton | 14ton |

| Machine dimensions (L×W×H) | 8000×3000×2000mm | 9200×2100×2000mm | 9200×2450×2000mm | 11000×3400×2000mm | 11000×3400×2000mm |