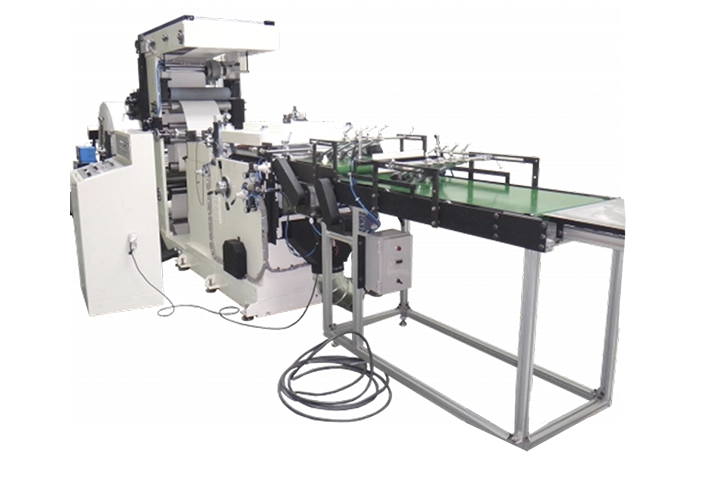

Flexo Printing and Die Cutting Machine

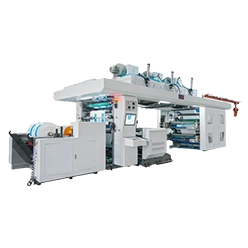

Flexo Printing and Die Cutting Machines are two distinct industrial machines commonly used in packaging production, labeling, printing, and related sectors. Often combined into a single integrated system, they perform multiple operations in one pass. Their functions are explained below.

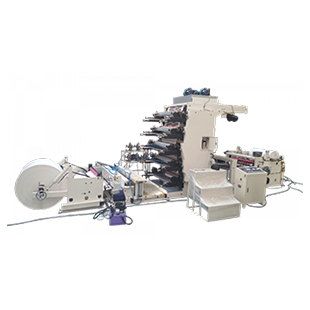

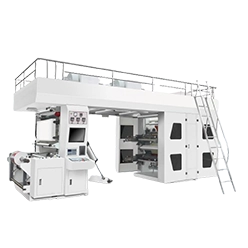

Working Principle of the Flexo Printing Machine

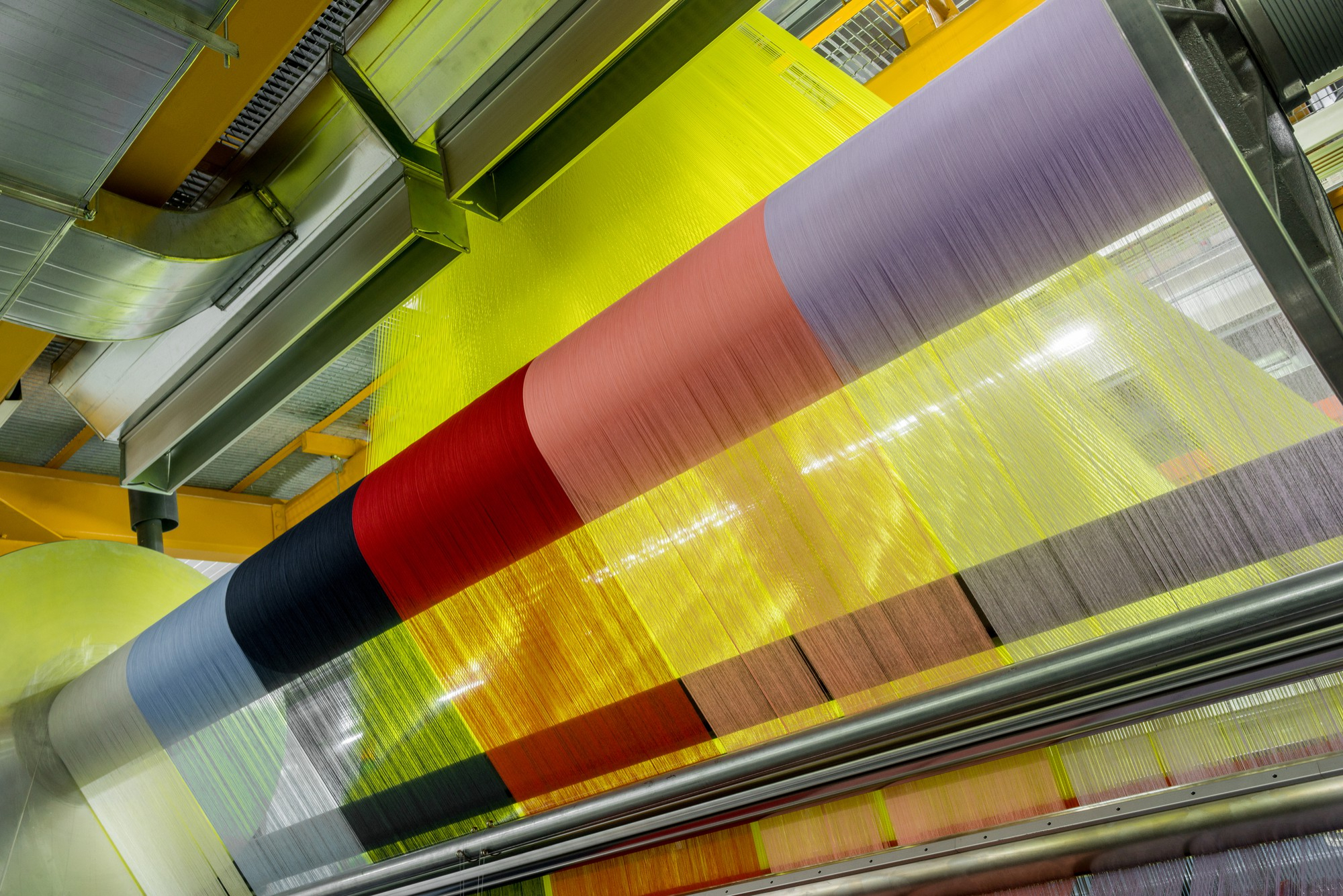

Flexo printing (flexography) is a printing technique primarily used for printing on flexible and durable materials. Flexo printers transfer ink via flexible printing plates. This method is widely applied in the packaging industry, particularly for printing on plastic, paper, cardboard, aluminum foil, and other flexible substrates.

Flexible Plates: Flexo printing uses flexible plates, often made from photopolymer materials, to transfer ink onto the substrate.

Ink Transfer: These plates transfer inks of various colors onto a cylinder or directly onto the printing surface. Unlike offset printing, the plate makes direct contact with the substrate to transfer the image.

Various Surfaces: Thanks to its flexibility, flexo printing can be applied on flat, cylindrical, round, and even irregularly shaped surfaces.

Advantages: Fast printing speeds, wide color options, compatibility with various materials, and the use of environmentally friendly inks are some of its key benefits.

Applications: Packaging (food, cosmetics, pharmaceutical packaging, etc.), label printing, paper and plastic products, outdoor advertising, and signage.

Working Principle of the Die Cutting Machine

Die cutting is a technique used to cut materials into specific shapes. These machines are typically employed after printing and often operate alongside flexographic printers. Die cutting is commonly used in packaging production, label cutting, and shaping paper, PVC, and various industrial products.

Cutting Dies: Die cutting machines use specialized wooden or metal cutting dies to cut materials into desired shapes. These dies are custom-designed according to the type of material and the required cut.

Cutting Process: After placing the material on the cutting bed, the machine presses the die to perform precise cuts, resulting in clean and accurate shapes.

High Precision: Die cutting machines can handle highly detailed and complex shapes, making them ideal for manufacturing labels, boxes, packaging, paper products, and more.

Applications: Packaging production (especially boxes, cardboard, PVC, plastic, and custom shape cutting), label cutting, metal and plastic industries, irregularly shaped products, fashion industry (e.g., leather cutting).