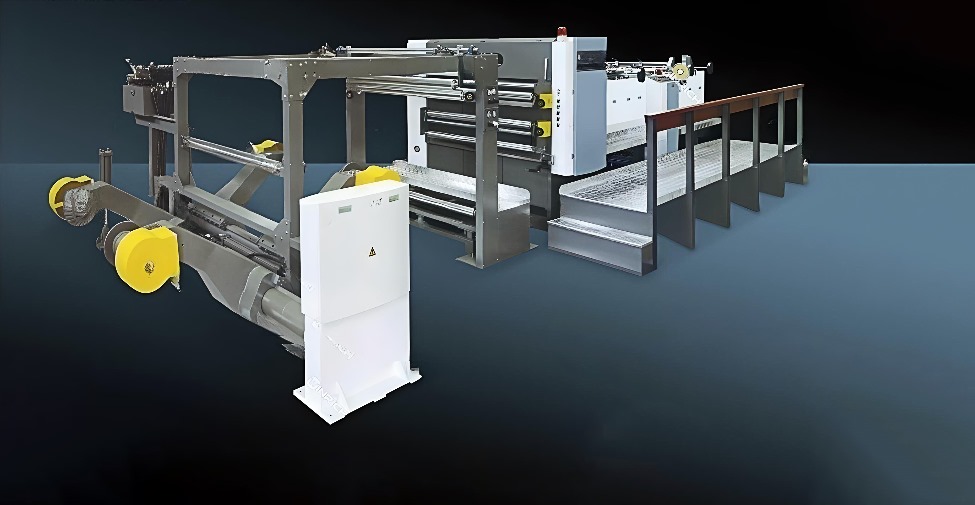

Medium Speed Paper Slitting and Rewinding Machine

Medium-Speed Paper Slitting and Rewinding Machine is one of our machines capable of efficiently slitting and rewinding paper rolls at a moderate speed. This machine is ideal for medium-scale production processes that do not require extremely high production speeds but still demand high-quality results. For slitting, adjustable rotary blades ensure high precision and ease of use. Independent air shafts are used for unwinding and rewinding. The machine is designed for easy setup, disassembly, and operation. Air shafts automatically control tension during unwinding and rewinding, ensuring that finished products are neatly and compactly rewound. The feeding support has an automatic pneumatic pressure lifting system, and an automatic waste disposal device is integrated.

Standard features of the machine include frequency speed control, PLC automatic control screen, hydraulic pressure correction device, automatic counting, alarm-based stopping, and a digital display for tension control. A dual servo motor system is used for controlling the rewinding shafts.

Features and Advantages of the Slitting and Rewinding Machine

Medium-Speed Operation: The medium-speed machine enables effective production with a slitting and rewinding speed of up to 260 meters per minute. It balances speed and quality, providing cost-effective solutions.

Flexible Slitting Capacity: The machine can process various paper types and thicknesses, with customizable slitting width and thickness according to user requirements.

Automatic Rewinding System: After slitting, the paper is automatically rewound, reducing labor efforts and accelerating production.

Low Operating Cost: Compared to high-speed machines, medium-speed machines operate at lower costs, making them highly advantageous for medium-scale production facilities.

Ease of Use and Maintenance: The medium-speed paper slitting machine has a simpler design, making it easier for operators to use and maintain with minimal costs and time investment.

Lower Energy Consumption: High-speed machines consume more energy, while medium-speed machines are energy-efficient, leading to long-term savings.

High-Quality Production: The medium-speed machine enables precise slitting and rewinding, ensuring consistently high-quality cuts.

Applications of the Paper Slitting and Rewinding Machine

Medium-Scale Production Facilities: Used in industries that require quality results without needing high-speed production.

Paper Industry: Ideal for slitting and rewinding large paper rolls into customized dimensions.

Packaging Sector: Commonly used for slitting and rewinding packaging paper or cardboard materials.

Printing Industry: Suitable for providing paper sheets in required sizes for printing machines that do not require high-speed operation.

| Model | KMPRSR-1100B | KMPRSR-1300B | KMPRSR-1600B |

| Maximum Unwinding Diameter | 1600mm | 1600mm | 1600mm |

| Minimum Slitting Width | 1000mm | 1200mm | 1500mm |

| Maximum Rewinding Diameter | 1000mm | 1000mm | 1000mm |

| Minimum Rewinding Width | 30mm | 30mm | 30mm |

| Slitting Speed | 10-260 m/min | 10-260 m/min | 10-260 m/min |

| Slitting Accuracy | ±0.3mm | ±0.3mm | ±0.3mm |

| Total Power | 12kw | 15kw | 16kw |

| Electricity | 380V/50Hz (Three-phase) | 380V/50Hz (Three-phase) | 380V/50Hz (Three-phase) |

| Air Pressure Supply Requirement | Max. 5.5kg/cm² x 0.5m³/min | Max. 5.5kg/cm² x 0.5m³/min | Max. 5.5kg/cm² x 0.5m³/min |

| Machine Weight | Approx. 5500kg | Approx. 6000kg | Approx. 7000kg |

| Machine Dimensions | 4000 × 3540 × 2200mm | 4000 × 3740 × 2200mm | 4000 × 4040 × 2200mm |