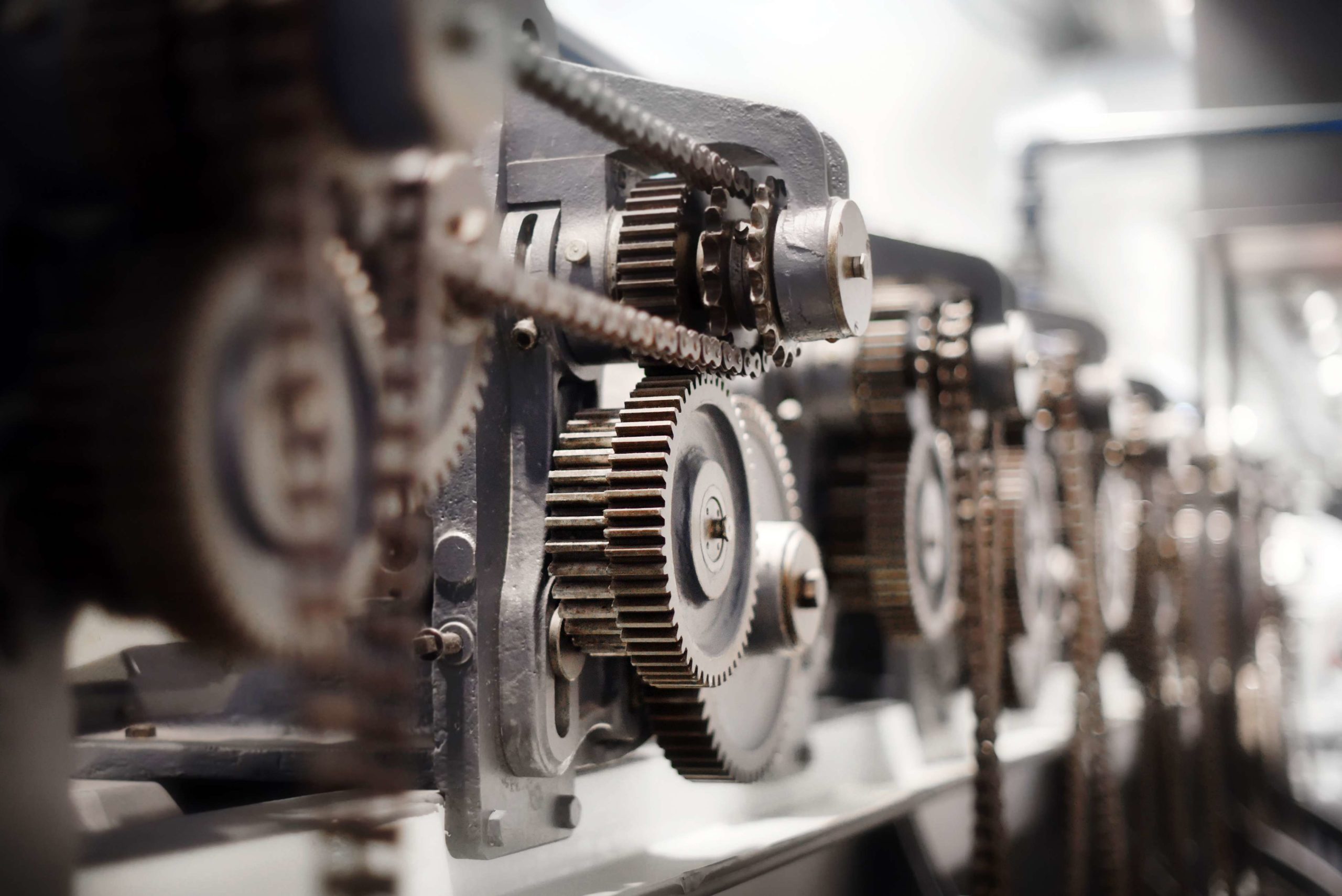

Lubricant oils are fluids that reduce friction between machine parts, preventing wear and ensuring more efficient operation of machines. They are used in many areas, from industrial machines and automotive engines to food processing machines and heavy construction equipment. These oils play a critical role in protecting mechanical systems, ensuring efficient operation, controlling temperature, and providing longevity.

Basic Functions of Lubricant Oils

-

Friction Reduction: Lubricant oils significantly reduce friction between two moving surfaces, preventing wear. This helps the machine operate efficiently and increases its lifespan.

-

Heat Distribution and Cooling: Oils help distribute heat generated within machines, preventing overheating and associated failures. Some oils also function as coolants, keeping machine temperature under control.

-

Protection: Lubricant oils protect metal surfaces, preventing rust, corrosion, and oxidation. This enhances the durability of machines and reduces maintenance needs.

-

Vibration and Noise Reduction: Oils reduce vibrations and noises within machines, ensuring quieter and smoother operation.

-

Cleaning: Lubricants prevent the accumulation of dirt, dust, and other contaminants in the system. Additionally, additives in the oil can help capture impurities.

Types of Lubricant Oils

-

Mineral Oils: These oils, derived from petroleum, are suitable for general-purpose use. They are usually more affordable and widely used in many industrial applications. These oils operate efficiently under normal temperature and pressure conditions.

-

Synthetic Oils: These oils are produced through chemical processes and generally provide higher heat resistance and longer lifespan. They are used in machines that operate under demanding conditions, requiring high performance. Synthetic oils are more resistant to temperature fluctuations due to their higher viscosity index.

-

Semi-Synthetic Oils: These are a mixture of mineral and synthetic oils. While generally more cost-effective, they offer lower properties compared to high-performance oils. However, they are not as durable as synthetic oils.

-

Biodegradable Oils: These environmentally friendly oils are especially used in industries like food and marine sectors. They possess properties that allow them to biodegrade without harming the environment.

-

Lubricating Fluids (Hydraulic Oils): These oils are used specifically in hydraulic systems. They provide efficient lubrication under high pressure and ensure safe operation of moving parts within the system.

-

Viscosity Oils: Viscosity refers to the degree of flowability of a liquid. Low-viscosity oils flow easily and have a thinner structure, while high-viscosity oils are denser and preferred for high-pressure systems.

Applications of Lubricant Oils

-

Automotive Industry: Used in motor oils, transmission oils, brake oils, power steering fluids, etc. These oils ensure that engines operate with high efficiency and prevent wear. They also regulate engine temperatures to prevent overheating.

-

Industrial Machines: Used in hydraulic machines, gear systems, compressors, and pumps. These oils provide high efficiency and long service life. Food-grade oils are also available for use in food processing machines.

-

Agricultural Machines: Used in tractors, harvesting machines, and other agricultural equipment. These machines often operate under challenging conditions, so durable and long-lasting oils are preferred.

-

Heavy Industry: Oils specifically formulated for large machines like mining equipment and metalworking machines, which operate in harsh conditions. These oils are resistant to excessive loads and tough environmental conditions.

-

Marine Industry: Used in ship engines and other maritime equipment. These oils are resistant to seawater effects and ensure long-term safe operation.

-

Energy and Electricity: Used in generators, wind turbines, power plants, etc. These oils play a critical role in ensuring high performance.

Advantages of Lubricant Oils

-

High Efficiency and Performance: Oils help machines operate more efficiently, leading to energy savings. Additionally, the performance of the machines is enhanced.

-

Increases Machine Lifespan: Oils prevent wear on machine parts, thus extending the machines’ lifespan. This also reduces maintenance and repair costs.

-

Low Maintenance Costs: Proper selection and use of oils prevent failures in machines, thus reducing maintenance costs.

-

Environmentally Friendly Options: Environmentally friendly oils can be used without harming the environment, thanks to their biodegradable formulas. These oils are especially preferred in the food industry and maritime applications.

-